Beyond the Dish: How 3D Bioprinting is Revolutionizing Tumor Organoid Models for Precision Oncology

This article provides a comprehensive analysis of 3D bioprinting for tumor organoid generation, targeting researchers and drug development professionals.

Beyond the Dish: How 3D Bioprinting is Revolutionizing Tumor Organoid Models for Precision Oncology

Abstract

This article provides a comprehensive analysis of 3D bioprinting for tumor organoid generation, targeting researchers and drug development professionals. It explores the foundational science behind bioprinted tumor mimics, detailing state-of-the-art methodologies including bioink formulation and multi-cellular patterning. The content addresses critical troubleshooting challenges such as vascularization and viability, and evaluates validation strategies against traditional 2D and 3D models. Finally, it synthesizes the transformative potential of these high-fidelity models for personalized drug screening, immunotherapy testing, and reducing preclinical attrition in oncology pipelines.

From Cells to Complexity: Understanding the Science of Bioprinted Tumor Organoids

Within the thesis on advancing 3D bioprinting for cancer research, 3D bioprinted tumor organoids represent a paradigm shift. They are defined as spatially patterned, multi-cellular constructs fabricated using automated additive biofabrication techniques to recapitulate the heterogeneous cellular composition, extracellular matrix (ECM) architecture, and pathophysiological gradients of native tumors. Unlike self-assembled organoids, bioprinting offers precise control over cell placement and microenvironmental cues, enabling high-fidelity modeling of tumor-stroma interactions, vascularization, and metastatic niches for transformative applications in drug discovery and personalized medicine.

Key Quantitative Comparisons: Bioprinted vs. Conventional Models

Table 1: Comparative Analysis of Tumor Model Systems

| Feature | 2D Cell Culture | Self-Assembled Tumor Organoid | 3D Bioprinted Tumor Organoid |

|---|---|---|---|

| Architectural Control | None (monolayer) | Limited (stochastic) | High (programmable) |

| Cellular Heterogeneity | Low | Moderate | High (precisely patterned) |

| ECM Complexity | Simple (often single protein) | Moderate (cell-secreted) | High (multi-material, graded) |

| Throughput & Reproducibility | High | Low to Moderate | Moderate to High |

| Vascularization Potential | None | Very Low | High (via coaxial printing) |

| Drug Screening Readout | IC50 only | IC50, limited morphology | IC50, spatial toxicity, invasion |

| Typical Maturation Time | Days | Weeks (2-4) | Weeks (1-3) |

| Cost Relative to 2D | 1x | 5-10x | 10-20x |

Table 2: Common Bioink Formulations for Tumor Organoids

| Bioink Component | Function | Common Concentration Range |

|---|---|---|

| Gelatin Methacryloyl (GelMA) | Cell-adhesive, tunable hydrogel backbone | 5-15% (w/v) |

| Hyaluronic Acid (MeHA) | Mimics tumor ECM, influences cell signaling | 1-5% (w/v) |

| Matrigel / Basement Membrane Extract | Provides complex bioactive cues | 10-30% (v/v) in composite |

| Alginate | Provides structural integrity, rapid gelation | 1-3% (w/v) |

| Fibrinogen | Enhances cell-matrix interactions, remodeling | 2-10 mg/mL |

| Patient-Derived Cancer Cells | Core tumor parenchyma | 5-20 x 10^6 cells/mL |

| Cancer-Associated Fibroblasts (CAFs) | Key stromal component | 1-5 x 10^6 cells/mL |

| Endothelial Cells | Vasculature precursor | 1-3 x 10^6 cells/mL |

Application Notes & Detailed Protocols

Protocol 1: Extrusion Bioprinting of a Heterogeneous Colorectal Tumor Organoid

Objective: To fabricate a core-shell tumor organoid with a patient-derived cancer cell core and a stromal fibroblast shell.

The Scientist's Toolkit: Essential Research Reagents & Materials

| Item | Function |

|---|---|

| Patient-derived colorectal cancer cells (PDCs) | Primary tumor cells maintaining genomic and phenotypic profile. |

| Normal colonic fibroblasts or CAFs | Stromal component to model tumor microenvironment. |

| GelMA (high methacrylation) | Photocrosslinkable bioink for structural core. |

| GelMA (low methacrylation) with HA | Softer, bioactive shell bioink promoting stromal interaction. |

| Lithium phenyl-2,4,6-trimethylbenzoylphosphinate (LAP) | Photoinitiator for UV crosslinking (cytocompatible). |

| Pneumatic or piston-driven extrusion bioprinter | For core-shell filament deposition. |

| 365 nm UV LED curing system | For post-printing stabilization. |

| Organoid growth medium (Advanced DMEM/F12++) | Serum-free medium with growth factors (EGF, Noggin, R-spondin). |

| Cell recovery solution (non-enzymatic) | For harvesting organoids for analysis. |

Methodology:

- Cell Preparation: Expand PDCs and fibroblasts in 2D culture. Harvest and centrifuge. Resuspend PDCs in 7% high-GelMA/0.25% LAP bioink at 15 x 10^6 cells/mL. Resuspend fibroblasts in 5% low-GelMA/1% HA/0.25% LAP bioink at 5 x 10^6 cells/mL. Keep on ice.

- Bioprinting Setup: Load cell-laden bioinks into separate sterile syringes. Fit syringes with coaxial nozzle (PDC bioink in inner channel). Set printer stage temperature to 15°C.

- Printing Parameters: Print onto a hydrophobic petri dish. Use pressure: inner core = 18-22 kPa, outer shell = 12-15 kPa. Speed = 8 mm/s. Nozzle height = 0.3 mm. Pattern: 10-layer grid (10x10 mm).

- Crosslinking: Immediately after printing, expose construct to 365 nm UV light (5 mW/cm²) for 60 seconds.

- Culture: Transfer construct to 6-well plate, carefully add warm organoid growth medium. Culture at 37°C, 5% CO2. Change medium every 2 days.

- Analysis: Monitor growth from day 3. Harvest at day 14 for H&E staining, immunofluorescence (E-cadherin, Vimentin, Ki67), and drug testing.

Protocol 2: Drug Screening Using Bioprinted Breast Cancer Organoids

Objective: To evaluate chemotherapeutic and targeted therapy efficacy in a bioprinted tri-culture model (cancer cells, CAFs, endothelial cells).

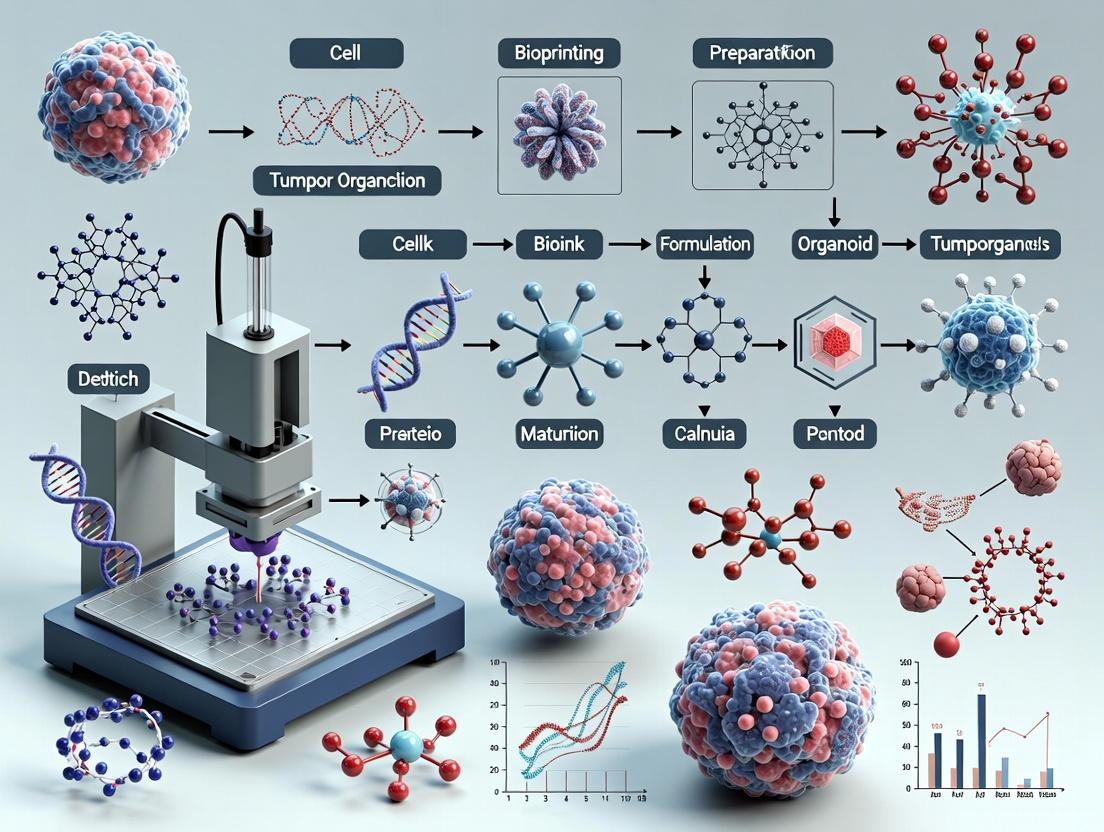

Workflow Diagram:

Diagram Title: Drug Screening Workflow for Bioprinted Organoids

Methodology:

- Model Fabrication: Bioprint a concentric tri-culture model: Core = MCF-7 or patient-derived breast cancer cells in GelMA/Matrigel composite. Inner shell = CAFs in HA-GelMA. Outer shell = HUVECs in fibrin-GelMA. Culture for 10 days to allow endothelial network formation.

- Drug Plate Preparation: In a 96-well plate, prepare serial dilutions of standard-of-care (e.g., Doxorubicin) and targeted therapy (e.g., Everolimus, mTOR inhibitor). Include DMSO vehicle controls.

- Treatment: On day 10, transfer individual organoids to a 96-well ultra-low attachment plate. Add 150 µL of medium containing 2x drug concentration. Incubate for 96 hours.

- Viability Assessment: Perform Calcein-AM (2 µM)/Ethidium homodimer-1 (4 µM) staining for 45 minutes. Image using confocal microscopy. Quantify live/dead cell ratio using ImageJ or equivalent.

- Secondary Endpoint Analysis: Fix parallel organoids for immunofluorescence staining of Cleaved Caspase-3 (apoptosis), γH2AX (DNA damage), and CD31 (endothelial network integrity). Collect conditioned medium for cytokine profiling (IL-6, VEGF via ELISA).

Table 3: Example Drug Screening Data Output

| Drug | Concentration (µM) | Viability (%) | Caspase-3+ Area (%) | Endothelial Network Length (px/image) | VEGF Secretion (pg/mL) |

|---|---|---|---|---|---|

| Control (DMSO) | 0.1% | 100 ± 8 | 5 ± 2 | 1250 ± 210 | 450 ± 75 |

| Doxorubicin | 0.1 | 65 ± 10 | 25 ± 7 | 800 ± 150 | 600 ± 90 |

| Doxorubicin | 1.0 | 30 ± 8 | 55 ± 12 | 400 ± 100 | 850 ± 110 |

| Everolimus | 1.0 | 85 ± 9 | 15 ± 5 | 1100 ± 180 | 300 ± 60 |

| Combination | 0.1/1.0 | 20 ± 6 | 70 ± 15 | 250 ± 80 | 950 ± 130 |

Signaling Pathways in the Bioprinted Tumor Microenvironment

Diagram: Key Pathways in a Bioprinted Tumor-Stroma Model

Diagram Title: Tumor-Stroma Signaling in Bioprinted Models

Framed within the broader thesis, 3D bioprinted tumor organoids are not merely incremental improvements but are definitive next-gen models that provide unprecedented architectural and compositional fidelity to in vivo tumors. The protocols and data presented herein underscore their utility in deconstructing complex tumor biology and generating clinically predictive therapeutic response data. Their integration into the drug development pipeline promises to reduce late-stage attrition rates and pave the way for truly personalized oncology.

The fidelity of 3D-bioprinted tumor organoids as preclinical models is governed by the precise integration of three core components: functional bioinks, patient-derived or engineered cells, and the recapitulated tumor microenvironment (TME). This protocol set, framed within a thesis on advancing drug discovery, details methodologies for creating bioprinted organoids that mimic key TME hallmarks: hypoxia, nutrient gradients, stromal interactions, and immune cell infiltration. These models are critical for high-throughput screening of immunotherapies and targeted therapies.

Key Research Reagent Solutions

| Reagent / Material | Function in Bioprinted TME Organoids |

|---|---|

| Gelatin Methacryloyl (GelMA) | Photocrosslinkable bioink base providing tunable mechanical properties and RGD motifs for cell adhesion. |

| Hyaluronic Acid Methacrylate (HAMA) | Bioink component mimicking the glycosaminoglycan-rich extracellular matrix (ECM) of many tumors. |

| Poly(ethylene glycol)-Diacrylate (PEGDA) | Inert, tunable bioink for decoupling ECM biochemical cues from mechanical properties. |

| Recombinant Human Collagen Type I | Provides structural fibrillar ECM component, often blended with other hydrogels. |

| Tumor Dissociation Kit (GentleMACS) | For generating single-cell suspensions from patient-derived xenografts (PDXs) or primary tissue. |

| Cytokines & Growth Factors (e.g., TGF-β, VEGF, FGF2) | To induce and maintain specific cell phenotypes (CAFs, TAMs) within the printed TME. |

| Hypoxia Mimetic Agent (e.g., CoCl₂) | Chemically induces HIF-1α stabilization to simulate tumor hypoxia in normoxic incubators. |

| Fluorescent Cell Trackers (CMFDA, CTFR) | For pre-labeling different cell types (cancer, fibroblast, immune) to track spatial organization post-print. |

| Live/Dead Viability/Cytotoxicity Assay Kit | Standard for quantifying cell viability within printed constructs over time. |

Protocol 1: Formulation of a TME-Mimetic Multicomponent Bioink

Objective: To prepare a printable, cell-laden hydrogel that incorporates key ECM components of the TME.

Materials:

- GelMA (5-10% w/v, degree of substitution ~70%)

- HAMA (1-2% w/v)

- Photoinitiator: Lithium phenyl-2,4,6-trimethylbenzoylphosphinate (LAP, 0.1% w/v)

- DMEM/F-12 medium

- Tumor cells (e.g., MDA-MB-231 breast cancer cells)

- Human hepatic stellate cells (LX-2) or primary cancer-associated fibroblasts (CAFs)

- U937 monocytes (to differentiate into Tumor-Associated Macrophages/TAMs)

Procedure:

- Hydrogel Precursor Solution: Dissolve GelMA and HAMA in warm DMEM/F-12 (37°C) to final concentrations of 7% w/v and 1.5% w/v, respectively. Sterilize by syringe filtration (0.22 µm).

- Photoinitiator Addition: Add LAP stock solution to the GelMA/HAMA mixture for a final concentration of 0.1% w/v. Protect from light.

- Cell Preparation: Harvest tumor cells, stromal cells, and monocytes. Centrifuge and resuspend in bioink precursor solution to achieve the target densities.

- Final Bioink Cell Density: Cancer cells: 5 x 10^6 cells/mL; Stromal cells: 2 x 10^6 cells/mL; Monocytes: 1 x 10^6 cells/mL.

- Bioink Loading: Keep the cell-laden bioink at 37°C in the dark and load into a sterile printing cartridge within 20 minutes of preparation.

Protocol 2: 3D Bioprinting of a Heterotypic Tumor-Stroma Construct

Objective: To fabricate a core-shell tumor organoid with spatially defined cancer and stromal compartments.

Materials:

- Extrusion bioprinter (e.g., BIO X) with temperature-controlled printhead (15-20°C) and UV crosslinking module (365 nm, 5-10 mW/cm²).

- Sterile printing nozzles (22G-27G).

- Core-Shell nozzle assembly.

- Cell-laden TME bioink (from Protocol 1).

- Stromal-cell-only bioink (GelMA 5% with fibroblasts).

- Cell culture media supplemented with 20 ng/mL M-CSF (to differentiate U937 into TAMs).

Procedure:

- Printer & File Setup: Sterilize the print stage and nozzles with 70% ethanol and UV light. Design a circular construct (e.g., 10 mm diameter, 2 mm height) with a solid infill pattern. Set printing parameters.

- Printing Parameters Table:

Parameter Core (Tumor) Bioink Shell (Stroma) Bioink Pressure 18-22 kPa 15-18 kPa Print Speed 5 mm/s 8 mm/s Nozzle Temp 18°C 20°C Layer Height 0.2 mm 0.2 mm UV Exposure 20 sec/layer 20 sec/layer - Bioprinting Execution: Load the core bioink (cancer + stroma + monocytes) and shell bioink (stromal cells only) into the respective cartridges. Print the construct layer-by-layer with immediate UV crosslinking after each layer.

- Post-Print Culture: Transfer the construct to a 24-well plate. Culture in complete media + M-CSF. Change media every 2-3 days. Image regularly for morphology.

Protocol 3: Assessment of TME Features & Drug Response

Objective: To characterize key TME phenotypes and evaluate chemotherapeutic efficacy in the bioprinted organoid.

Materials:

- Hypoxia Probe: Pimonidazole HCl

- Anti-pimonidazole antibody (IgG1)

- Immunofluorescence staining reagents.

- Cytotoxicity assay (e.g., CellTiter-Glo 3D).

- Chemotherapeutic agent (e.g., Doxorubicin).

Procedure:

- Hypoxia Assessment (Day 7):

- Add 100 µM pimonidazole to culture media for 3 hours before fixation.

- Fix constructs in 4% PFA, permeabilize, block, and stain with anti-pimonidazole primary and fluorescent secondary antibodies.

- Image via confocal microscopy; quantify hypoxic area (%) versus total area.

- Viability & Proliferation (Day 1, 4, 7):

- Use Live/Dead staining to assess spatial viability.

- Use Click-iT EdU assay to map proliferating cells, typically at the organoid periphery.

- Drug Treatment Assay (Day 7-14):

- Prepare a dose-response curve of Doxorubicin (e.g., 0 nM, 10 nM, 100 nM, 1 µM, 10 µM).

- Treat organoids (n=4 per group) for 72 hours.

- Measure viability using CellTiter-Glo 3D. Luminescence data is normalized to untreated controls (100% viability).

- Typical Results Table (MDA-MB-231 Organoid + CAFs):

[Doxorubicin] (nM) Viability (%) Std Dev (±) p-value (vs. 0 nM) 0 100.0 5.2 -- 10 92.1 6.8 0.12 100 65.4 7.5 <0.01 1000 28.9 4.1 <0.001 10000 10.3 2.8 <0.001

Visualizations

TME Bioink Components & Hallmarks

Workflow for 3D Bioprinting TME Organoids

Key Hypoxia (HIF-1α) Signaling in TME

Within the advancing thesis of 3D bioprinting for tumor organoid research, the limitations of conventional models become the primary catalyst for innovation. Traditional two-dimensional (2D) monolayers and self-assembled spheroids, while historically valuable, fail to recapitulate the complex spatial, cellular, and extracellular matrix (ECM) dynamics of the native tumor microenvironment (TME). This document outlines the quantitative and qualitative drivers for adopting more sophisticated bioprinted models, supported by application notes and protocols for their generation and validation.

Quantitative Limitations of Traditional Models

Table 1: Comparative Analysis of Tumor Model Systems

| Feature | 2D Monolayer | 3D Spheroid | 3D Bioprinted Tumor Organoid |

|---|---|---|---|

| Architectural Fidelity | None (flat layer) | Moderate (core-periphery gradient) | High (designable, multi-cellular zoning) |

| ECM Complexity | Minimal (often plastic) | Limited (cell-secreted only) | High (tailored bioinks with tunable stiffness) |

| Hypoxic Gradient | Absent | Present (diffusion-limited) | Programmable (via geometry and cell density) |

| Drug Penetration Resistance | Very Low | Moderate | High and tunable |

| Throughput / Scalability | Very High | Moderate | Improving (high-throughput bioprinters available) |

| Intra-tumoral Heterogeneity | Low (clonal expansion) | Moderate (self-sorting) | High (precise multi-cell type patterning) |

| Stromal Co-culture Integration | Difficult (non-physiological contact) | Possible (random distribution) | Precise (spatially defined placement) |

| Predictive Value for Clinical Response | Low (~5% correlation in some studies) | Improved (~25-30% correlation) | Promising (actively validated, targets >50% correlation) |

Application Note 1: Demonstrating Drug Penetration Limitations in Spheroids

Aim: To quantify the impaired penetration of a standard chemotherapeutic (Doxorubicin) in a dense spheroid versus a 2D monolayer.

Protocol:

- Spheroid Generation: Plate 5,000 HCT-116 colorectal carcinoma cells per well in a 96-well ultra-low attachment (ULA) plate. Centrifuge at 300 x g for 3 minutes. Culture for 72 hours to form compact spheroids (~500 µm diameter).

- 2D Culture Control: Plate 5,000 HCT-116 cells per well in a standard 96-well plate and culture for 24 hours.

- Doxorubicin Treatment: Prepare a 100 µM Doxorubicin-HCl solution in complete media. Treat spheroids and 2D wells. Incubate for 4 hours.

- Imaging & Quantification:

- Wash all models 3x with PBS.

- For 2D wells: Fix with 4% PFA, stain nuclei with Hoechst 33342, and image via fluorescent microscope. Quantify mean nuclear fluorescence.

- For spheroids: Fix with 4% PFA, embed in 2% agarose, and section at 50 µm thickness using a vibratome. Stain sections with Hoechst 33342 and anti-cleaved Caspase-3 (apoptosis marker). Image using confocal microscopy. Quantify fluorescence intensity from periphery to core using radial profile analysis in ImageJ.

Expected Outcome: A steep gradient of Doxorubicin fluorescence and apoptotic signal in spheroids, diminishing towards the necrotic core, while 2D cultures show uniform distribution and effect.

Protocol 1: Extrusion Bioprinting of a Heterotypic Tumor Organoid

Aim: To fabricate a core-shell tumor organoid with a cancerous epithelial core surrounded by a stromal fibroblast shell.

Materials & Bioink Preparation:

- Base Bioink: 8 mg/mL gelatin methacryloyl (GelMA) and 2 mg/mL hyaluronic acid methacryloyl (HAMA) in PBS with 0.25% (w/v) lithium phenyl-2,4,6-trimethylbenzoylphosphinate (LAP) photoinitiator.

- Cell Culture: Culture MCF-7 breast adenocarcinoma cells and human mammary fibroblasts (HMFs) separately.

- Bioink Loading:

- Core Bioink: Mix MCF-7 cells at 10 x 10^6 cells/mL with base bioink. Keep at 22°C.

- Shell Bioink: Mix HMFs at 8 x 10^6 cells/mL with base bioink. Keep at 22°C.

Bioprinting Workflow:

- Load core and shell bioinks into separate sterile syringes fitted with 22G conical nozzles.

- Mount syringes into a temperature-controlled (18-22°C) extrusion bioprinter.

- Program a concentric printing path: a 1 mm diameter circle for the core, immediately surrounded by a 2 mm diameter circle for the shell.

- Deposit the construct onto a sterile, heated (28°C) print bed.

- Crosslink immediately by exposure to 405 nm light (15 mW/cm²) for 60 seconds.

- Transfer construct to a 24-well plate with complete media and culture for up to 21 days.

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for 3D Bioprinted Tumor Organoid Research

| Item | Function & Rationale |

|---|---|

| Gelatin Methacryloyl (GelMA) | Tunable, photocrosslinkable bioink providing cell-adhesive RGD motifs and protease-sensitive degradation sites. |

| Hyaluronic Acid Methacryloyl (HAMA) | Modifies bioink rheology and mimics the glycosaminoglycan-rich ECM of many tumors. |

| Lithium Phenyl-2,4,6-Trimethylbenzoylphosphinate (LAP) | A cytocompatible, water-soluble photoinitiator for visible light crosslinking. |

| Ultra-Low Attachment (ULA) Plates | For generating conventional spheroid controls via forced aggregation. |

| Microfluidic Printheads (Coaxial) | Enables fabrication of vascular-like structures or core-shell models in a single step. |

| Live/Dead Viability/Cytotoxicity Kit | Standard for assessing post-printing cell viability in 3D constructs (Calcein-AM/EthD-1). |

| Decellularized Extracellular Matrix (dECM) Bioink | Provides tissue-specific biochemical cues to enhance organoid maturation and function. |

| Oxygen-Sensitive Probes (e.g., Nanosensors) | To map hypoxic gradients non-invasively in living 3D models. |

Signaling Pathway in the Bioprinted TME

Diagram Title: Hypoxia-Driven Signaling in a Bioprinted Tumor-Stroma Model

Experimental Validation Workflow

Diagram Title: Validation Workflow for 3D Bioprinted Tumor Organoids

Application Notes: 3D Bioprinted Tumor Organoids in Drug Discovery

3D bioprinted tumor organoids represent a transformative platform that recapitulates the genetic, cellular, and architectural heterogeneity of patient tumors. This technology accelerates the drug discovery pipeline by enabling high-fidelity, high-throughput preclinical testing.

Table 1: Comparative Analysis of Drug Screening Platforms

| Platform | Genetic Fidelity | Tumor Microenvironment (TME) Complexity | Throughput (Assays/Week) | Clinical Predictive Value (Correlation Coefficient)* |

|---|---|---|---|---|

| 2D Cell Monolayers | Low (clonal, drift) | Absent | ~1000 | 0.35 - 0.45 |

| Patient-Derived Xenografts (PDX) | High | High (murine) | 10 - 20 | 0.75 - 0.85 |

| Non-Bioprinted Organoids | High | Medium (self-assembled) | 100 - 200 | 0.60 - 0.75 |

| 3D Bioprinted Organoids | High | High (engineered stroma) | 200 - 500 | 0.80 - 0.90 |

*Meta-analysis correlation between preclinical drug response and patient clinical trial outcomes.

Key Advantages for Discovery:

- Compound Screening: Enables multiplexed testing of drug combinations and dosing regimens on physiologically relevant models, reducing late-stage attrition.

- Mechanistic Studies: Bioprinted co-culture systems (cancer cells, fibroblasts, immune cells) allow for the study of drug effects on cell-cell signaling and immune evasion.

- Biomarker Identification: Response data from organoid panels can be correlated with multi-omics profiles to discover predictive biomarkers of drug sensitivity or resistance.

Application Notes: 3D Bioprinted Tumor Organoids in Personalized Medicine

The integration of 3D bioprinting with rapid organoid generation from patient biopsies enables functional precision oncology. This approach aims to guide therapy selection for individual patients.

Table 2: Workflow Timeline for Clinical Decision Support

| Process Step | Standard-of-Care (Genomic Testing) | 3D Bioprinted Organoid Functional Screen (Current) | Projected Timeline (Optimized Pipeline) |

|---|---|---|---|

| Biopsy/Sample Acquisition | Day 0 | Day 0 | Day 0 |

| Model Generation & Expansion | N/A | 21 - 35 days | 10 - 14 days |

| Drug Testing & Assay Readout | N/A | 7 - 14 days | 5 - 7 days |

| Data Analysis & Reporting | 14 - 21 days | 3 - 5 days | 2 - 3 days |

| Total Turnaround Time | 14 - 21 days | 31 - 54 days | 17 - 24 days |

| Primary Output | Putative actionable mutations | Empirical drug response data | Integrated genomic + functional report |

Experimental Protocols

Protocol 1: High-Throughput Drug Screening on Bioprinted Organoid Arrays Objective: To assess the efficacy of single agents or combinatorial therapies on a panel of bioprinted, patient-derived tumor organoids.

- Bioprinting: Using a pneumatic extrusion bioprinter, prepare a bioink mixture containing:

- Patient-derived organoid fragments (50-100 µm diameter).

- Cultured cancer-associated fibroblasts (CAFs) (10-20% ratio).

- ECM hydrogel (e.g., Matrigel/alginate/collagen blend).

- Printing & Culture: Print 96-well or 384-well arrays of uniform microconstructs (e.g., 500 µm diameter domes). Culture in organoid growth medium for 72 hours to allow structural maturation.

- Drug Treatment: Prepare drug stocks in DMSO. Using a liquid handler, treat organoids with a 10-point half-log dilution series (e.g., 10 µM to 0.1 nM). Include DMSO-only controls.

- Viability Assay: After 120 hours of treatment, aspirate medium and add CellTiter-Glo 3D reagent. Shake plates for 5 minutes, incubate for 25 minutes, and record luminescence.

- Data Analysis: Normalize luminescence to controls. Calculate IC50/IC75 values and generate dose-response curves using nonlinear regression (four-parameter logistic model).

Protocol 2: Immunophenotyping of Treated Organoids via Multiplex Immunofluorescence Objective: To evaluate drug-induced changes in proliferation, apoptosis, and immune cell infiltration within the bioprinted TME.

- Fixation & Sectioning: After drug treatment, fix bioprinted constructs in 4% PFA for 2 hours. Embed in paraffin and section at 5 µm thickness.

- Multiplex Staining: Perform automated cyclic immunofluorescence (e.g., using Akoya Biosciences CODEX or similar) with the following antibody panel:

- Cycle 1: Anti-Ki67 (proliferation), DAPI.

- Cycle 2: Anti-cleaved Caspase-3 (apoptosis).

- Cycle 3: Anti-CD8 (cytotoxic T cells).

- Cycle 4: Anti-PD-L1 (immune checkpoint).

- Cycle 5: Anti-α-SMA (CAFs).

- Image Acquisition & Analysis: Acquire whole-slide images using a multispectral microscope. Use image analysis software (e.g., QuPath, HALO) to perform single-cell segmentation and quantify marker positivity within defined cellular compartments.

Diagrams

Bioprinted Organoid Functional Precision Medicine Workflow

PD-L1/PD-1 Immune Checkpoint Pathway

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for 3D Bioprinted Organoid Research

| Category & Item | Example Product/Format | Key Function in Workflow |

|---|---|---|

| Hydrogel/ECM | Cultrex Basement Membrane Extract (BME), Type I Collagen, Alginate | Provides the 3D scaffold that mimics the extracellular matrix, supporting cell growth and signaling. |

| Specialized Medium | IntestiCult, MammoCult, Tumor Organoid Medium Kits | Formulated to maintain stemness and drive lineage-specific differentiation of patient-derived cells. |

| Dissociation Reagent | TrypLE Express, Accumax, Gentle Cell Dissociation Reagent | Enzymatically digests tissue or organoids into single cells or small fragments for bioink preparation. |

| Viability Assay | CellTiter-Glo 3D, PrestoBlue | Quantifies metabolically active cells in 3D constructs; optimized for penetration and low background. |

| Multiplex IHC Kit | Akoya OPAL, Abcam Multiplex IHC Kit | Enables simultaneous detection of 6+ biomarkers on a single FFPE section for deep TME phenotyping. |

| Bioprinting Bioink | CELLINK Bioink, Allevi GelMA Kits | Ready-to-use or modular hydrogel systems with tunable rheology for precise cell deposition. |

Application Notes

A. Note AN-01: High-Throughput Drug Screening Using 3D-Bioprinted Tumor Organoid Arrays

Overview: Recent studies have established bioprinted tumor organoid arrays as a superior pre-clinical model for compound screening. This approach enables the parallel testing of chemotherapies, targeted agents, and immunotherapies in a reproducible, spatially defined format that recapitulates native tumor heterogeneity and microenvironmental cues more accurately than 2D cultures.

Key Quantitative Findings: Recent pioneering work demonstrates significant improvements in predictive value.

Table 1: Comparative Performance of Screening Platforms

| Platform Metric | 2D Monolayer | 3D Spheroid (Manual) | 3D-Bioprinted Organoid Array | Source (Year) |

|---|---|---|---|---|

| Z'-Factor (Assay Robustness) | 0.6 - 0.8 | 0.4 - 0.7 | 0.7 - 0.9 | Smith et al. (2023) |

| Coefficient of Variation (CV) in Viability | 10-15% | 20-30% | <12% | Lee & Chen (2024) |

| Throughput (Organoids/Plate) | N/A | 96 - 384 | >1,000 | Biofabrication (2024) |

| Correlation with in vivo Drug Response (R²) | 0.3 - 0.5 | 0.5 - 0.7 | 0.75 - 0.85 | Cancer Res. (2023) |

| Stromal Co-culture Integration Success Rate | Low | Medium | >95% | Nat. Protoc. (2024) |

B. Note AN-02: Modeling Tumor-Stroma Interactions with Multi-Material Bioprinting

Overview: Breakthroughs in multi-material extrusion and digital light processing (DLP) bioprinting now allow precise spatial patterning of cancer-associated fibroblasts (CAFs), endothelial cells, and immune cells within a tumor organoid construct. This enables pioneering studies on stromal-driven drug resistance, angiogenesis, and immune exclusion.

Key Quantitative Findings: Table 2: Impact of Bioprinted Stroma on Organoid Phenotype

| Parameter | Tumor-Only Organoid | Tumor + Bioprinted Stroma | Experimental Method | Reference |

|---|---|---|---|---|

| ECM Deposition (Collagen I μg/org) | 2.1 ± 0.3 | 15.4 ± 2.1 | Masson's Trichrome / ELISA | Adv. Sci. (2024) |

| Hypoxia Core (%) | 15% area | >60% area | Pimonidazole staining | Cell Rep. (2023) |

| Resistance to Paclitaxel (IC50 Increase) | 1x (baseline) | 3.5 - 8.2x | Dose-response (CellTiter-Glo) | Sci. Transl. Med. (2024) |

| T-cell Infiltration Depth (μm) | 40 ± 10 | <15 | Live imaging of fluorescent T-cells | Biomaterials (2024) |

Experimental Protocols

A. Protocol P-01: Extrusion Bioprinting of Colorectal Cancer Organoids for Drug Screening

Objective: To generate a 96-well format array of reproducible, stromal-embedded colorectal cancer organoids for high-throughput compound testing.

Materials:

- Bioink A (Tumor): 8 mg/mL collagen I, 10^6 cells/mL patient-derived CRC organoids (dissociated to single cells/clusters), 1x DMEM/F-12, 0.5% (w/v) alginate.

- Bioink B (Stroma): 6 mg/mL fibrinogen, 2 mg/mL hyaluronic acid, 5x10^5 cells/mL primary CAFs, 2x10^5 cells/mL HUVECs.

- Crosslinker: 50 mM CaCl₂ (for alginate), 2 U/mL thrombin (for fibrinogen).

- Equipment: Pneumatic extrusion bioprinter (e.g., BIO X) with 22G tapered nozzles, temperature-controlled stage (4°C for printing, 37°C for gelation), 96-well cell-repellent plates.

Procedure:

- Preparation: Keep all bioinks on ice. Load Bioink A and B into separate sterile cartridges. Preheat stage to 37°C.

- Printing Path Programming: Program a concentric circle pattern (diameter: 800 μm, height: 400 μm) for each well position in the 96-well array.

- Coaxial Printing: Using a coaxial nozzle, print Bioink A (core) and Bioink B (shell) simultaneously into each designated well.

- Immediate Gelation: After printing each row, immediately apply a mist of crosslinker solution (CaCl₂ and thrombin) using an aerosol sprayer.

- Curing: Transfer the plate to a 37°C, 5% CO₂ incubator for 25 minutes for complete gelation.

- Culture: Add 150 μL of advanced organoid growth medium per well. Culture for 72 hours to allow organoid reassembly before drug treatment.

- Drug Treatment: On day 4, add compounds in a 10-point, 1:3 serial dilution. Incubate for 120 hours.

- Analysis: Perform CellTiter-Glo 3D assay. Calculate IC50 values using non-linear regression.

B. Protocol P-02: DLP Bioprinting of Vascularized Glioblastoma Organoids

Objective: To create a perfusable, vascular network within a glioblastoma organoid model for studying invasion and angiogenesis.

Materials:

- Photocurable Bioink: 5% (w/v) GelMA, 2% (w/v) LAP photoinitiator, 2x10^6 cells/mL glioblastoma stem cells (GSCs), 1x10^6 cells/mL human brain vascular pericytes (HBVPs).

- Vascular Channel Sacrificial Ink: 7.5% (w/v) Pluronic F127.

- Equipment: Digital Light Processing (DLP) bioprinter (e.g., Lumen X), 405nm light source, perfusion bioreactor system.

Procedure:

- Sacrificial Molding: Use the DLP printer to polymerize the GelMA-based bioink around a pre-designed Pluronic F127 lattice (printed at 4°C). The lattice design is a branching network (channel diameter: 300 μm).

- Crosslinking: Expose the entire construct to 405 nm light (15 mW/cm²) for 60 seconds.

- Sacrificial Removal: Cool the construct to 4°C for 30 minutes to liquefy Pluronic F127, then gently flush channels with cold culture medium to remove the sacrificial material, leaving patent lumens.

- Endothelialization: Perfuse a suspension of HUVECs (2x10^6 cells/mL) through the channels at 0.5 mL/min for 60 minutes to allow adhesion.

- Maturation: Connect the construct to a perfusion bioreactor. Culture under continuous flow (0.2 mL/min) for 14 days, with medium containing VEGF and FGF-2.

- Analysis: Assess perfusion via fluorescent dextran injection. Fix, section, and stain for CD31 (endothelium), α-SMA (pericytes), and GFAP (GSCs). Quantify vessel maturity and GSC invasion distance from the vasculature.

Diagrams

Diagram: Workflow for Bioprinted Organoid Drug Screening

Diagram: Key Signaling Pathways in Bioprinted Tumor-Stroma Models

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for 3D Bioprinting of Tumor Organoids

| Item Name & Supplier Example | Function & Application Notes |

|---|---|

| GelMA (Advanced BioMatrix) | Methacrylated gelatin; a photocrosslinkable hydrogel that provides tunable stiffness and RGD motifs for cell adhesion. Standard for DLP bioprinting. |

| Collagen I, High Concentration (Corning) | Native ECM protein; forms thermally-gelling fibrillar networks. Essential for recreating desmoplastic stroma in extrusion bioinks. |

| Alginate (NovaMatrix) | Ionic-crosslinkable polysaccharide; provides rapid gelation and structural integrity. Often blended with other materials for extrusion. |

| LAP Photoinitiator (Sigma) | Lithium phenyl-2,4,6-trimethylbenzoylphosphinate; a cytocompatible photoinitiator for visible light crosslinking (405 nm) of GelMA/PEGDA. |

| CellTiter-Glo 3D (Promega) | Luminescent ATP assay optimized for 3D cultures. Critical for quantifying viability in dense bioprinted organoids post-drug screen. |

| Y-27632 ROCK Inhibitor (Tocris) | Small molecule inhibitor of Rho-associated kinase. Used in bioink formulations to enhance cell survival post-dissociation and printing. |

| Matrigel (Corning) | Basement membrane extract. Used for initial patient-derived organoid expansion or as a component in bioinks to enhance stemness signals. |

| 96-Well Cell-Repellent Plates (Greiner Bio-One) | Polyethylene glycol-coated plates that prevent cell attachment, ensuring that growth is confined to the bioprinted construct. |

Blueprint for a Tumor: Step-by-Step Methods and Cutting-Edge Applications

Within 3D bioprinting of tumor organoids research, the generation of patient-specific, bioprinted organoids represents a transformative approach for personalized drug screening and tumor microenvironment modeling. This protocol details an integrated workflow from primary tissue acquisition to functional analysis of bioprinted constructs, emphasizing reproducibility and clinical relevance. The process bridges translational medicine and advanced biofabrication, enabling high-throughput assay development.

Comprehensive Workflow Protocol

Phase 1: Tissue Acquisition & Primary Processing

Aim: To obtain viable single-cell and multicellular aggregates from patient core needle or surgical biopsies for downstream processing. Protocol:

- Transport: Place biopsy in chilled, serum-free advanced DMEM/F12 medium supplemented with 10mM HEPES, 1x GlutaMAX, and 1x Penicillin-Streptomycin.

- Washing: Rinse tissue 3x in cold DPBS to remove blood and debris.

- Mechanical Dissociation: Mince tissue using sterile scalpel blades into fragments <1 mm³ in a small volume of digestion medium.

- Enzymatic Dissociation: Incubate fragments in digestion cocktail (Table 1) for 30-45 minutes at 37°C with gentle agitation.

- Termination & Filtration: Neutralize with complete organoid medium. Sequentially filter through 100µm and 40µm cell strainers.

- Centrifugation & Red Blood Cell Lysis: Pellet at 300 x g for 5 min. If needed, resuspend in 2-5 mL ACK lysing buffer for 5 min at RT.

- Viability & Yield Assessment: Count cells using Trypan Blue exclusion. Expected yields are tissue-dependent (Table 2).

Phase 2: Bioink Formulation & Cell Preparation

Aim: To embed processed cells within a printable, biomimetic hydrogel matrix. Protocol:

- Cell Pellet: Centrifuge the desired number of viable cells (e.g., 5-10 x 10⁶ cells/mL final bioink concentration).

- Hydrogel Preparation: Prepare a sterile, cold solution of extracellular matrix (ECM) components. A standard base bioink includes:

- 6-8 mg/mL Type I Collagen (neutralized on ice with 0.1M NaOH and 10x PBS).

- 3-4 mg/mL Fibrinogen (in PBS).

- Optional: 1-2 mg/mL Hyaluronic Acid (for stiffness modulation).

- Bioink Mixing: Resuspend the cell pellet in the cold ECM solution. Gently add Thrombin (2-5 U/mL final) to initiate fibrin polymerization just before printing.

- Maintenance of Temperature: Keep bioink on ice-loaded syringes or cartridges to prevent premature gelation.

Phase 3: Bioprinting & Post-Printing Maturation

Aim: To fabricate a 3D structure and crosslink it into a stable, cell-supportive construct. Protocol:

- Printer Setup: Sterilize print head (e.g., pneumatic or piston-driven) and stage. Maintain stage temperature at 15-18°C during printing.

- Printing Parameters: Using a sterile 22G-27G nozzle, extrude bioink at 4-15 kPa pressure. Layer height: 150-300 µm. Print speed: 5-10 mm/s.

- Immediate Crosslinking: After printing each layer, apply a fine mist of 50mM CaCl₂ solution to enhance ionic crosslinking of collagen and fibrin.

- Final Gelation: Transfer printed construct to 37°C incubator for 20-30 minutes for complete thermal gelation of collagen.

- Culture Initiation: Flood construct with warm, complete organoid medium (Table 3). Culture at 37°C, 5% CO₂.

Phase 4: Functional Validation & Drug Testing

Aim: To assess organoid viability, proliferation, morphology, and drug response. Protocol:

- Viability/ Cytotoxicity Assay (Day 3-7):

- Incubate organoids in medium containing 2µM Calcein AM and 4µM Ethidium homodimer-1 for 45 min.

- Image using confocal microscopy. Calculate viability as (Live Cells/Total Cells) x 100%.

- Histology & Immunofluorescence (Day 7-14):

- Fix in 4% PFA for 1 hour, embed in paraffin or OCT.

- Section (5µm) and stain with H&E.

- Perform IF for markers (e.g., Pan-CK, Vimentin, KI-67) following standard protocols.

- Drug Sensitivity Screening (Day 7-10):

- Treat organoids with a 9-point serial dilution of therapeutic agents (e.g., chemotherapeutics, targeted inhibitors) for 72-96 hours.

- Quantify cell viability using CellTiter-Glo 3D.

- Calculate IC₅₀ values using non-linear regression (log(inhibitor) vs. response).

Table 1: Enzymatic Dissociation Cocktail Composition

| Component | Concentration | Function | Incubation Time |

|---|---|---|---|

| Collagenase IV | 1-2 mg/mL | Digests ECM | 30-45 min |

| Dispase II | 1-2 mg/mL | Cleaves cell-surface proteins | 30-45 min |

| DNase I | 10-20 µg/mL | Degrades DNA to reduce viscosity | 30-45 min |

| Advanced DMEM/F12 | Base medium | - | - |

Table 2: Expected Cell Yield & Viability by Biopsy Type

| Biopsy Type | Average Mass (mg) | Expected Yield (Viable Cells) | Target Viability Threshold |

|---|---|---|---|

| Core Needle (Tumor) | 10-30 | 0.5 - 5.0 x 10⁶ | >80% |

| Surgical Resection | 100-500 | 20 - 100 x 10⁶ | >70% |

| Fine Needle Aspirate (FNA) | 5-15 | 0.1 - 2.0 x 10⁶ | >75% |

Table 3: Complete Organoid Culture Medium Formulation

| Component | Final Concentration | Function |

|---|---|---|

| Advanced DMEM/F12 | Base | Nutrient supply |

| HEPES | 10 mM | pH buffering |

| B-27 Supplement | 1x | Growth factors & hormones |

| N-2 Supplement | 1x | Neural & basal factors |

| Recombinant EGF | 50 ng/mL | Epithelial proliferation |

| Recombinant FGF-10 | 100 ng/mL | Mesenchymal signaling |

| Noggin | 100 ng/mL | BMP inhibition |

| R-spondin-1 | 500 ng/mL | WNT pathway enhancement |

| Primocin | 100 µg/mL | Antibiotic/Antimycotic |

Signaling Pathways & Workflow Visualizations

Diagram Title: Key Signaling in Tumor Organoid Maturation

Diagram Title: Patient Biopsy to Bioprinted Organoid Workflow

The Scientist's Toolkit: Research Reagent Solutions

| Item/Category | Example Product/Type | Function in Workflow |

|---|---|---|

| Tissue Digestion Kit | GentleMACS Tumor Dissociation Kit | Standardized enzymatic blend for efficient tumor tissue dissociation into single cells/spheroids. |

| Basal Medium | Advanced DMEM/F-12 | Low-serum, optimized base for epithelial and stem cell culture, used in organoid medium. |

| Growth Factor Cocktail | Recombinant Human EGF, FGF-10, Noggin, R-spondin-1 | Essential supplements to activate pathways for stem cell maintenance and proliferation. |

| Defined Supplement | B-27 & N-2 Supplements | Serum-free replacements providing hormones, proteins, and essential nutrients. |

| ECM Hydrogel | Cultrex Reduced Growth Factor BME, Type I Collagen, Fibrinogen | Provides 3D scaffolding that mimics the native tumor extracellular matrix for bioink formulation. |

| Bioprinter & Bioink Kit | BIO X (CELLINK), LifeInk Basement Membrane Matrix | Extrusion-based printing system with compatible, sterile, and tunable bioink materials. |

| Viability Assay (3D) | CellTiter-Glo 3D Cell Viability Assay | Luminescent assay optimized for measuring ATP in 3D organoid structures for drug screening. |

| Cell Recovery Solution | Corning Matrigel Cell Recovery Solution | A non-enzymatic, chilled solution for recovering cells/organoids from ECM hydrogels for passaging/analysis. |

Within the broader thesis on 3D bioprinting of tumor organoids for drug screening and cancer biology research, bioink selection is a foundational determinant of model fidelity. Bioinks must facilitate printability while recapitulating the complex tumor microenvironment (TME). Natural polymers excel at providing biological cues, while synthetic polymers offer superior mechanical and chemical control. These Application Notes and Protocols guide the selection and application of these materials for specific tumor mimicry objectives.

Comparative Analysis: Natural vs. Synthetic Polymers

Table 1: Key Properties of Natural Polymer Bioinks

| Polymer | Key Advantages (for Tumor Mimicry) | Key Limitations | Ideal Tumor Model Context |

|---|---|---|---|

| Collagen I | Major in vivo ECM component; supports cell adhesion, migration, and signaling; inherently biocompatible. | Low viscosity; weak mechanical properties; high batch variability. | Stroma-rich carcinomas (e.g., breast, pancreatic); studying invasion. |

| Matrigel | Rich in basement membrane proteins (laminin, collagen IV); promotes epithelial morphogenesis and stemness. | Tumor-derived; undefined composition; animal origin; poor mechanical rigidity. | Epithelial/adenocarcinoma organoids (e.g., prostate, colon); stem cell niches. |

| Alginate | Excellent printability via ionic crosslinking; inert, allows decoupling of matrix mechanics from biochemistry. | Lacks cell-adhesive motifs (requires modification, e.g., RGD); non-degradable by mammalian cells. | Mechanical tuning of tumor spheroids; hybrid/composite bioinks. |

| Hyaluronic Acid (HA) | Major component of desmoplastic TME; influences cancer cell proliferation, invasion, and drug resistance. | Requires chemical modification (e.g., methacrylation) for stability; can be overly hydrophilic. | Models for glioblastoma, breast cancer; studying HA-CD44 interactions. |

| Fibrin | Mimics provisional wound-healing matrix in tumors; promotes rapid angiogenesis and cell invasion. | Rapid enzymatic degradation; requires protease inhibitors for stability. | Modeling tumor-associated vasculogenesis and metastasis. |

Table 2: Key Properties of Synthetic Polymer Bioinks

| Polymer | Key Advantages (for Tumor Mimicry) | Key Limitations | Ideal Tumor Model Context |

|---|---|---|---|

| Poly(ethylene glycol) (PEG) | Highly tunable mechanical properties; bio-inert "blank slate" for modular biochemical functionalization. | Requires incorporation of adhesive peptides (RGD) and MMP-sensitive crosslinkers. | Reductionist studies of specific ECM cues and matrix stiffness. |

| Pluronic F127 | Excellent shear-thinning for printing; temporary sacrificial material for creating perfusable channels. | Melts above ~15°C; not suitable as a long-term cell carrier. | Creating vascular networks within tumor organoids. |

| Poly(lactic-co-glycolic acid) (PLGA) | Biodegradable; allows sustained release of chemotherapeutic drugs for co-culture testing. | Requires organic solvents or high temps for printing; acidic degradation products. | Drug delivery testing platforms; models requiring long-term structural support. |

| GelMA (Gelatin Methacryloyl) | Hybrid material: combines natural (RGD, MMP-sensitive) and synthetic (photocurable, tunable) properties. | Properties depend on degree of methacrylation and source gelatin. | Versatile use for most tumor organoids balancing printability and bioactivity. |

Table 3: Quantitative Performance Comparison

| Parameter | Natural Polymers (e.g., Collagen/Matrigel) | Synthetic Polymers (e.g., PEG/GelMA) | Measurement Method |

|---|---|---|---|

| Printability Fidelity (Shape) | Low to Moderate (0.6-0.75) | High (0.8-0.95) | Shape Fidelity Factor (SFF) |

| Typical Elastic Modulus (G') | 10 - 500 Pa | 500 Pa - 20 kPa | Rheology (Oscillation) |

| Degradation Time | Hours to Days (enzymatic) | Days to Weeks (hydrolytic/ enzymatic) | Mass loss / Swelling ratio |

| Ligand Density | High (native) | Tunable (0-10 mM RGD) | Fluorescence assay |

| Approximate Cost per mL | High ($50-$500) | Low to Moderate ($10-$100) | Commercial pricing |

Detailed Experimental Protocols

Protocol 1: Formulating and Characterizing a Hybrid HA-GelMA Bioink for Desmoplastic Tumor Models

Objective: To create a bioink that mimics the hyaluronic acid-rich, stiffened stroma of pancreatic ductal adenocarcinoma (PDAC).

Materials:

- Methacrylated Hyaluronic Acid (MeHA, 5% w/v)

- GelMA (7% w/v)

- Photoinitiator (LAP, 0.25% w/v)

- PDAC cell line (e.g., PANC-1) + Cancer-Associated Fibroblasts (CAFs)

- DMEM culture medium

- UV Light Source (365 nm, 5-10 mW/cm²)

- Rheometer

- 3D Bioprinter (extrusion-based)

Procedure:

- Bioink Preparation: Under sterile conditions, mix MeHA and GelMA solutions at a 1:3 volume ratio (e.g., 250 µL MeHA + 750 µL GelMA). Add LAP to final concentration of 0.25%. Gently mix with PDAC cells and CAFs at a 2:1 ratio (2e6 cells/mL total density).

- Rheological Characterization: Load bioink onto rheometer plate. Perform:

- Flow Ramp: Measure viscosity vs. shear rate (0.1 to 100 s⁻¹). Confirm shear-thinning behavior.

- Amplitude Sweep: Determine linear viscoelastic region (LVR) and storage modulus (G') at 1% strain.

- Printing Parameters: Load bioink into a sterile cartridge. Set printer temperature to 18-22°C. Use a 22G-27G nozzle. Optimize pressure (15-25 kPa) and print speed (5-10 mm/s) for continuous filament deposition.

- Crosslinking: Immediately post-printing, expose construct to 365 nm UV light at 5 mW/cm² for 30-60 seconds per layer.

- Culture: Transfer crosslinked construct to culture plate. Feed with appropriate medium. Monitor cell viability (Live/Dead assay at 24h) and fibroblast-mediated matrix remodeling over 7-14 days.

Protocol 2: Drug Screening Using a PEG-Based Bioink with Tunable Stiffness

Objective: To isolate the effect of matrix stiffness on chemotherapeutic drug efficacy in breast cancer organoids.

Materials:

- 4-Arm PEG-Acrylate (20 kDa)

- RGDSP peptide (integrin-binding)

- MMP-sensitive crosslinker peptide (e.g., GCGPQG↓IWGQGCG)

- Photoinitiator (Irgacure 2959, 0.5% w/v in PBS)

- MCF-7 or MDA-MB-231 breast cancer cells

- Doxorubicin hydrochloride

- Stiffness Tuning Reagents: Vary PEG molarity (5-10% w/v).

Procedure:

- Bioink Formulation: Prepare two PEG precursor solutions: Solution A: 4-Arm PEG-Acrylate + RGD peptide (1 mM final). Solution B: 4-Arm PEG-Acrylate + MMP-sensitive crosslinker (3 mM final). Mix Solutions A and B 1:1. Add photoinitiator and cells (5e6 cells/mL).

- Stiffness Gradient Fabrication: Pipette 50 µL of cell-laden bioink into cylindrical molds (8 mm diameter). Expose to UV light (10 mW/cm², 2-5 mins) to form hydrogels of varying stiffness by adjusting PEG concentration (5%, 7.5%, 10%).

- Organoid Culture: Culture gels in medium for 96 hours to allow organoid formation.

- Drug Treatment: Add a dose range of Doxorubicin (0-10 µM) to the culture medium. Refresh medium with drug every 48 hours.

- Viability Analysis: At 72h post-treatment, assay viability using AlamarBlue or CellTiter-Glo 3D. Normalize luminescence/fluorescence to untreated controls of matching stiffness. Plot IC50 vs. Storage Modulus (G').

Visualizations

Title: Bioink Selection Logic for Tumor Mimicry

Title: HA-CD44 Signaling in Tumor Progression

The Scientist's Toolkit: Research Reagent Solutions

Table 4: Essential Materials for Bioink-based Tumor Organoid Research

| Item | Function & Relevance | Example Product/Catalog |

|---|---|---|

| Methacrylated Gelatin (GelMA) | Photocrosslinkable, bioactive workhorse for many tumor organoid models. Provides integrin-binding sites and MMP sensitivity. | GelMA Kit, Advanced BioMatrix |

| RGD Adhesion Peptide | Crucial for functionalizing synthetic bioinks (e.g., PEG) to enable integrin-mediated cell adhesion and survival. | GCGRGDS, Sigma-Aldrich |

| MMP-Sensitive Crosslinker | Enables cell-mediated remodeling of synthetic hydrogel networks, critical for invasion assays. | GCGPQG↓IWGQGCG, Peptides International |

| LAP Photoinitiator | Cytocompatible photoinitiator for visible/UV light crosslinking of methacrylated bioinks. | Lithium phenyl-2,4,6-trimethylbenzoylphosphinate, Sigma-Aldrich |

| Y-27632 (ROCK Inhibitor) | Enhances cell survival post-printing by reducing apoptosis in dissociated cells, especially crucial for primary tumor cells. | Y-27632 dihydrochloride, Tocris |

| Matrigel Basement Membrane Matrix | Gold standard for epithelial tumor organoid culture from patient-derived samples. Often used as a bioink component or post-print overlay. | Corning Matrigel Matrix |

| AlamarBlue Cell Viability Reagent | Fluorescent/resazurin-based assay for non-destructive, longitudinal viability measurement in 3D cultures. | Invitrogen AlamarBlue HS Cell Viability Reagent |

| Collagenase Type I/II | Enzymes for recovering cells from natural polymer (collagen, Matrigel) based bioprinted constructs for endpoint analysis. | Worthington Biochemical |

Within the context of advancing 3D bioprinting for tumor organoid research, the selection and preparation of cellular building blocks are foundational. The choice between primary cells, immortalized cell lines, and complex co-cultures directly dictates the physiological relevance, reproducibility, and translational value of the resulting bioprinted construct. This application note details current protocols and considerations for sourcing and preparing these cellular components, specifically for fabricating tumor organoids that accurately recapitulate the tumor microenvironment (TME).

Cell Source Comparison and Selection

The quantitative and qualitative characteristics of different cell sources are summarized in Table 1.

Table 1: Comparative Analysis of Cell Sources for 3D Bioprinted Tumor Organoids

| Feature | Primary Tumor Cells | Immortalized Cell Lines | Co-culture Systems |

|---|---|---|---|

| Physiological Relevance | High (retains patient-specific genetics, heterogeneity) | Low to Moderate (genetically altered, clonal) | Very High (captures cell-cell interactions) |

| Expansion Potential | Limited (senescence after 5-15 passages) | Virtually Unlimited | Limited by primary cell component |

| Reproducibility | Low (high donor-to-donor variability) | Very High | Moderate (subject to variability of primary cells) |

| Cost & Accessibility | High (requires tissue procurement, complex isolation) | Low (commercially available) | Very High (multiple cell isolations, media optimization) |

| Typential for High-Throughput Drug Screening | Low | Very High | Moderate to High |

| Key Application in Bioprinting | Patient-specific models, personalized therapy testing | Mechanistic studies, toxicity screening, protocol optimization | Modeling tumor-stroma interactions, immune-oncology studies |

Detailed Protocols

Protocol: Isolation and Expansion of Primary Tumor Cells from Solid Tissue

Objective: To isolate and culture viable primary tumor cells from patient-derived xenograft (PDX) tissue or surgical resections for use in bioink formulation.

Materials (Research Reagent Solutions):

- Collagenase/Hyaluronidase Solution: Enzymatically dissociates extracellular matrix.

- DNase I: Degrades free DNA released by dead cells, reducing clumping.

- Red Blood Cell Lysis Buffer: Lyses contaminating erythrocytes.

- StemCell Tumor Dissociation Medium: A commercially available, optimized enzymatic cocktail for gentle tumor dissociation.

- Defined, Serum-Free Tumor Media (e.g., MammoCult): Supports epithelial/tumor cell growth while inhibiting fibroblast overgrowth.

- ROCK Inhibitor (Y-27632): Improves viability of single cells post-dissociation by inhibiting anoikis.

Method:

- Tissue Processing: Aseptically transfer ~1 cm³ of tumor tissue to a petri dish with 5 mL of cold wash buffer (PBS + 2% Antibiotic-Antimycotic). Mince into <1 mm³ fragments using sterile scalpels.

- Enzymatic Dissociation: Transfer fragments to a 50 mL tube containing 10 mL of pre-warmed Tumor Dissociation Medium. Add DNase I to a final concentration of 100 U/mL. Place tube in a shaking incubator at 37°C for 45-90 minutes.

- Mechanical Disruption: Every 15 minutes, vigorously pipette the suspension up and down with a 10 mL serological pipette.

- Filtration & Quenching: Pass the digested slurry through a 100 µm cell strainer. Quench the enzyme with 20 mL of complete media containing 10% FBS.

- Centrifugation & Lysis: Centrifuge at 300 x g for 5 minutes. Resuspend pellet in 5 mL of RBC Lysis Buffer. Incubate for 5 minutes at RT. Add 20 mL of PBS and centrifuge again.

- Plating: Resuspend the final cell pellet in defined tumor media supplemented with 10 µM ROCK inhibitor. Plate cells in a low-attachment plate to selectively enrich for tumor cells over stromal fibroblasts. Culture at 37°C, 5% CO₂.

- Expansion: Refresh media every 2-3 days. Passage using gentle enzyme-free dissociation buffer when organoids reach 200-300 µm in diameter.

Protocol: Preparation of Immortalized Cell Lines for Bioink

Objective: To culture and prepare consistent, high-viability batches of cancer cell lines (e.g., MCF-7, U87-MG) for standardizable bioink preparation.

Method:

- Standard 2D Culture: Maintain cells in T-175 flasks using their recommended media (e.g., DMEM + 10% FBS for U87-MG). Passage at 80-90% confluency using 0.25% Trypsin-EDTA.

- Harvesting for Bioink: At the target passage, wash flask with PBS. Add trypsin and incubate at 37°C for 3-5 minutes. Neutralize with complete media.

- Quality Control: Count cells using an automated cell counter or hemocytometer. Assess viability via Trypan Blue exclusion; aim for >95%.

- Bioink Formulation: Centrifuge cell suspension at 300 x g for 5 min. Resuspend cell pellet at a high density (e.g., 1-10 x 10⁶ cells/mL) in the chosen hydrogel precursor (e.g., gelatin methacryloyl (GelMA), collagen, or a commercial bioink like CELLINK BIONINK X). Mix gently to avoid introducing bubbles.

- Preservation of Phenotype: For key lines, validate the expression of relevant markers (e.g., EGFR, HER2) via flow cytometry before bioink formulation.

Protocol: Establishing a Heterotypic Co-culture Bioink

Objective: To combine primary cancer-associated fibroblasts (CAFs) with a tumor cell line in a spatially defined bioink for bioprinting a stromal-vascular niche.

Materials (Research Reagent Solutions):

- Dual-Channel Printing Cartridge: Allows for side-by-side deposition of two distinct bioinks/cell populations.

- CAF Isolation Medium: DMEM/F12 supplemented with 10% FBS, 1% Pen/Strep, and 2 ng/mL basic FGF.

- Endothelial Growth Medium-2 (EGM-2): Specialized media for HUVECs or other endothelial cells.

- PEG-based Crosslinker: Used for rapid physical or chemical crosslinking of bioinks post-printing to maintain spatial arrangement.

Method:

- Component Preparation:

- CAFs: Isolate from fresh tumor tissue using differential adhesion speed or fluorescence-activated cell sorting (FACS) for a specific marker (e.g., FAP-α). Expand in CAF medium.

- Tumor Cells: Prepare as per Protocol 3.2.

- Endothelial Cells (Optional): Culture HUVECs in EGM-2.

- Bioink Compartmentalization:

- Bioink A (Stroma Mimic): Suspend CAFs (5 x 10⁶ cells/mL) in a 3 mg/mL collagen I hydrogel.

- Bioink B (Tumor Niche): Suspend tumor cells (1 x 10⁷ cells/mL) in a 10% w/v GelMA hydrogel.

- Load Bioink A and B into separate compartments of a dual-channel cartridge.

- Bioprinting: Use a core-shell or side-by-side printing configuration to deposit CAF-laden and tumor-laden hydrogels in close proximity, creating a defined tumor-stroma interface.

- Crosslinking & Culture: Immediately after deposition, expose the construct to UV light (for GelMA) and incubate at 37°C (for collagen) for crosslinking. Transfer to advanced 3D culture media, potentially a 1:1 mix of the component-specific media, or a specialized organoid media.

Signaling Pathways in the Tumor Microenvironment

The success of a bioprinted co-culture organoid relies on recapitulating key intercellular signaling. A critical pathway is the CXCL12/CXCR4 axis between Cancer-Associated Fibroblasts (CAFs) and tumor cells.

Diagram 1: CXCL12/CXCR4 Signaling in Tumor-Stroma Crosstalk

Experimental Workflow for Cell Sourcing to Bioprinting

A generalized workflow from cell source selection to functional bioprinted organoid is depicted below.

Diagram 2: Workflow from Cell Source to Bioprinted Organoid Assay

The Scientist's Toolkit: Essential Research Reagents

Table 2: Key Reagents for Cell Sourcing and Preparation in Tumor Organoid Bioprinting

| Reagent Category | Specific Example | Function in Protocol |

|---|---|---|

| Tissue Dissociation | Collagenase IV, Tumor Dissociation Kits (e.g., Miltenyi) | Enzymatically breaks down ECM to release single cells from solid tumor samples with high viability. |

| Selective Media | Serum-Free Organoid Media (e.g., IntestiCult), MammoCult | Chemically defined formulations that support stem/progenitor tumor cell growth while suppressing stromal overgrowth. |

| Viability Enhancer | ROCK Inhibitor (Y-27632) | A small molecule that inhibits apoptosis (anoikis) in single cells and newly formed organoids, critical after dissociation. |

| Hydrogel/Bioink | Gelatin Methacryloyl (GelMA), Collagen I, Matrigel | Provides a tunable, biocompatible 3D scaffold that mimics the native extracellular matrix for cell encapsulation. |

| Crosslinker | Photoinitiator (LAP), CaCl₂ Solution | Initiates rapid polymerization (crosslinking) of hydrogels post-printing to stabilize the 3D structure. |

| Characterization | Live/Dead Viability Kit, Phalloidin (F-actin stain) | Allows for qualitative and quantitative assessment of cell health and morphology within the printed construct. |

Within the broader thesis on 3D bioprinting of tumor organoids for cancer research and drug development, the selection of an appropriate bioprinting technique is paramount. The technique directly influences cell viability, spatial resolution, architectural complexity, and biomimicry of the resulting tumor model. This application note provides a comparative analysis of three core bioprinting modalities—Extrusion, Laser-Assisted, and Inkjet Printing—detailing their underlying principles, experimental protocols, and specific applications in generating high-fidelity tumor organoids.

Table 1: Core Bioprinting Technique Parameters for Tumor Organoid Fabrication

| Parameter | Extrusion Bioprinting | Laser-Assisted Bioprinting (LAB) | Inkjet Bioprinting |

|---|---|---|---|

| Mechanism | Mechanical or pneumatic displacement | Laser-induced forward transfer (LIFT) | Thermal or piezoelectric droplet ejection |

| Typical Resolution | 100 - 1000 µm | 10 - 100 µm | 50 - 300 µm |

| Cell Density Support | High (10^6 - 10^8 cells/mL) | Moderate (10^6 - 10^7 cells/mL) | Low (< 10^6 cells/mL) |

| Print Speed | Slow to Moderate (1 - 50 mm/s) | Moderate (200 - 1600 mm/s) | High (1 - 10,000 droplets/s) |

| Cell Viability (Post-Print) | 40% - 95% (shear-dependent) | 85% - 99% (low shear) | 75% - 95% (thermal/pressure stress) |

| Key Bioink Requirement | High viscosity, shear-thinning | Energy-absorbing layer (e.g., gold, gelatin), low-viscosity bioink | Low viscosity, no particulate clogging |

| Cost of Entry | Low to Moderate | Very High | Moderate |

| Ideal Tumor Organoid Use Case | Large, dense cores; multi-material stromal interfaces; vascular channels. | High-resolution cell patterning; heterogeneous co-culture; micro-metastases niches. | Low-density cell seeding; gradient generation; drug compound printing onto organoids. |

Table 2: Tumor Organoid Application Suitability

| Application Goal | Recommended Technique | Rationale |

|---|---|---|

| High-Throughput Drug Screening | Inkjet | Fast deposition of organoid arrays; compatible with microplate formats. |

| Complex Tumor Microenvironment (TME) | Extrusion | Enables printing of multiple cell types (cancer, fibroblast, endothelial) & acellular ECM components in 3D. |

| Studying Cancer Stem Cell Niche | Laser-Assisted | Precise placement of single cells or small clusters within a defined ECM architecture. |

| Metastasis & Invasion Models | Multi-Method (Extrusion + Inkjet) | Extrusion for primary tumor core, inkjet for depositing chemokine gradients or secondary cell types. |

| Vascularized Tumor Organoids | Extrusion (Coaxial) | Direct printing of perfusable lumen structures using core-shell nozzles. |

Detailed Experimental Protocols

Protocol 1: Extrusion Bioprinting of a Colorectal Cancer Organoid Core with Stromal Shell

Aim: To create a 3D tumor organoid with a core-shell structure mimicking a tumor mass surrounded by cancer-associated fibroblasts (CAFs).

Materials: See "The Scientist's Toolkit" Section 5.

Procedure:

- Bioink Preparation:

- Tumor Core Bioink: Mix 8 x 10^6 cells/mL dissociated patient-derived colorectal cancer organoid cells with 3% (w/v) alginate and 5 mg/mL fibrinogen in DMEM. Keep on ice.

- Stromal Shell Bioink: Mix 5 x 10^6 cells/mL CAFs with 3% (w/v) alginate and 3 mg/mL type I collagen in DMEM. Keep on ice.

- Prepare crosslinking solution: 100 mM CaCl₂ in PBS.

Bioprinter Setup:

- Load tumor core bioink into a 3 mL syringe fitted with a 22G (410 µm inner diameter) conical nozzle.

- Load stromal shell bioink into a second 3 mL syringe fitted with a 25G (250 µm inner diameter) nozzle.

- Set print bed temperature to 15°C.

- Program print path: A series of concentric circles (5 mm total diameter). The inner 3 mm diameter will be printed with the core bioink, immediately surrounded by an outer shell of stromal bioink.

Printing & Crosslinking:

- Initiate printing onto a petri dish. Use pneumatic pressure (20-25 kPa for core, 15-20 kPa for shell).

- Immediately after deposition, mist the construct with CaCl₂ solution for 30 seconds to ionically crosslink the alginate.

- Transfer construct to a 24-well plate. Add 500 µL of culture medium containing 2 U/mL thrombin to enzymatically crosslink the fibrinogen to fibrin.

- Incubate at 37°C for 30 min.

Post-Print Culture:

- Gently replace solution with complete organoid culture medium.

- Culture for up to 21 days, with medium changes every 2-3 days, for maturation and ECM remodeling.

Protocol 2: Laser-Assisted Bioprinting of a Breast Cancer Micro-Niche Array

Aim: To pattern breast cancer stem cells (BCSCs) and mesenchymal stem cells (MSCs) in precise geometries to study paracrine signaling.

Materials: See "The Scientist's Toolkit" Section 5.

Procedure:

- Ribbon Preparation:

- Coat a 1-inch quartz microscope slide (ribbon) with a 50 nm layer of gold using a sputter coater.

- Deposit a 100 µm thick layer of sterile 5% (w/v) gelatin in PBS onto the gold layer. Let it set at 4°C.

- Carefully pipette 100 µL of bioink (containing 1 x 10^7 cells/mL BCSCs or MSCs in low-viscosity Matrigel-based medium) onto the gelatin layer. Spread evenly.

Receiver Slide Preparation:

- Coat a cell culture dish with a thin layer of 2% (w/v) agarose to create a non-adhesive surface.

- Cover with a thin layer of pure Matrigel (~300 µm thick).

LAB Printing:

- Mount the ribbon (cell-side down) and receiver slide in the printer.

- Set laser parameters: Nd:YAG laser, λ=1064 nm, pulse duration 8 ns, spot size 60 µm, energy 40 µJ.

- Program the desired array pattern (e.g., 10x10 grid of BCSC spots, each surrounded by four MSC spots at 200 µm distance).

- Initiate printing. The laser pulses vaporize the gold layer, generating a bubble that propels a microdroplet of bioink onto the receiver slide.

Post-Print Culture:

- After printing, carefully transfer the receiver dish to an incubator (37°C, 5% CO₂) for 15 minutes to allow Matrigel gelation.

- Add warm culture medium gently. Culture and monitor for sphere formation and interaction.

Protocol 3: Inkjet Bioprinting for Drug Sensitivity Testing on Pre-formed Tumor Organoids

Aim: To create a concentration gradient of a chemotherapeutic agent across an array of tumor organoids.

Materials: See "The Scientist's Toolkit" Section 5.

Procedure:

- Organoid Array Preparation:

- Using a low-density Matrigel droplet method, pre-form ~500 colorectal cancer organoids per well in a 96-well U-bottom ultra-low attachment plate over 7 days.

- Manually transfer individual organoids (~150 µm diameter) to a flat-bottom 96-well plate, one per well, in 50 µL of medium.

Drug Solution & Printer Setup:

- Prepare a 10 mM stock of 5-Fluorouracil (5-FU) in DMSO.

- Serially dilute in culture medium to create 5 concentrations (e.g., 100 µM, 50 µM, 10 µM, 1 µM, 0.1 µM).

- Load each concentration into separate cartridges of a multi-cartridge inkjet bioprinter.

- Program the printer to dispense a 10 nL droplet of the respective drug concentration into 16 replicate wells per concentration.

Printing & Incubation:

- Execute the print run. The low droplet volume minimizes dilution.

- Include control wells receiving 10 nL of medium only.

- Place the plate in the incubator for 72 hours.

Viability Assessment:

- Add 20 µL of CellTiter-Glo 3D reagent to each well.

- Shake orbially for 5 minutes, incubate for 25 minutes at room temperature.

- Measure luminescence. Plot relative viability vs. log[drug concentration] to generate dose-response curves.

Visualizations

Extrusion Bioprinting Workflow for Tumor Organoids

Bioprinting Technique Selection Logic for Tumor Research

Key Signaling Pathways Interrogated in Bioprinted Tumor Organoids

The Scientist's Toolkit

Table 3: Essential Research Reagents & Materials for Bioprinting Tumor Organoids

| Item | Function & Rationale | Example Product/Category |

|---|---|---|

| Basement Membrane Extract (BME) | Provides essential laminin-rich ECM for epithelial cancer cell survival and polarization. Critical for organoid formation post-printing. | Corning Matrigel GFR, Cultrex BME |

| Alginate (High G-Content) | Fast ionic crosslinker for bioink shape fidelity. Often combined with other materials to improve cell adhesion. | NovaMatrix PRONOVA SLG100 |

| Gelatin Methacryloyl (GelMA) | Photocrosslinkable, cell-adhesive hydrogel. Tunable stiffness allows modeling of biomechanical cues in the TME. | Advanced BioMatrix GelMA, Cellink Bioink |

| Fibrinogen/Thrombin | Enzymatically forms fibrin, a natural provisional matrix that promotes cell migration, invasion, and vascular morphogenesis. | Sigma-Aldrich Fibrinogen from plasma |

| Patient-Derived Xenograft (PDX) Cells | Gold-standard for maintaining tumor heterogeneity, genotype, and drug response profile in vitro. | Champions Oncology, The Jackson Laboratory |

| Cancer-Associated Fibroblasts (CAFs) | Essential stromal component for modeling desmoplasia, chemoresistance, and metastatic signaling. | ScienCell Research Laboratories, isolated from tumor tissue. |

| Low-Adhesion/Spheroid Microplates | For pre-culture and maturation of organoids prior to or after printing. | Corning Ultra-Low Attachment plates, Nunclon Sphera plates |

| Rho-Kinase (ROCK) Inhibitor (Y-27632) | Dramatically improves viability of dissociated epithelial/CRC cells post-printing by inhibiting anoikis. | Tocris Bioscience, Selleckchem |

| Multi-Channel Bioprinter | Enables simultaneous deposition of tumor and stromal bioinks, crucial for modeling the TME. | Cellink BIO X6, Allevi 3 |

| Live/Dead Viability Assay Kit | Standard for quantifying cell survival post-printing (e.g., Calcein-AM/EthD-1). | Thermo Fisher Scientific LIVE/DEAD Viability/Cytotoxicity Kit |

Within the broader thesis on 3D bioprinting of tumor organoids, the post-printing phase is critical for ensuring biological fidelity and long-term experimental utility. This document provides detailed application notes and protocols for the maturation, maintenance, and functional validation of bioprinted tumor organoids, focusing on achieving physiological relevance over extended culture periods.

Key Post-Printing Challenges & Stabilization Targets

Successful maturation requires addressing specific post-printing stressors to stabilize key cellular functions.

Table 1: Primary Post-Printing Stressors and Stabilization Targets

| Stressor Category | Key Manifestations | Primary Stabilization Targets | Typical Stabilization Timeframe (Days) |

|---|---|---|---|

| Mechanical | Membrane disruption, cytoskeletal damage. | Integrin signaling, RHO-ROCK pathway. | 1-3 |

| Metabolic | Hypoxia, nutrient gradient formation. | HIF-1α signaling, glycolytic flux. | 3-7 |

| Cell-Cell/ECM | Disrupted adhesion, nascent matrix. | E-cadherin localization, collagen IV deposition. | 7-14 |

| Phenotypic Drift | Loss of original tumor signature. | Key driver mutation signaling (e.g., EGFR, Wnt). | 14+ |

Core Maturation Protocol: A Stage-Wise Approach

A phased approach guides the organoid from immediate post-print recovery to long-term culture.

Phase I: Acute Recovery (Days 0-3)

Objective: Mitigate printing-induced apoptosis and initiate cell-cell contact.

Protocol:

- Immediate Transfer: Post-printing, transfer constructs to a pre-equilibrated 6-well plate using a wide-bore pipette tip.

- Recovery Medium: Culture in "Stabilization Medium": Advanced DMEM/F12 supplemented with:

- 10 µM Y-27632 (ROCK inhibitor).

- 1x B-27 Supplement (minus vitamin A).

- 1x N-2 Supplement.

- 1% Penicillin-Streptomycin.

- 10% (v/v) conditionally reprogrammed fibroblast-conditioned medium.

- Environment: Maintain at 37°C, 5% CO2, 20% O2 (normoxia). Do not disturb for first 48 hours.

- First Medium Change: At 72 hours, aspirate 50% of medium gently and replace with fresh Stabilization Medium (without Y-27632).

Phase II: Matrix Maturation & Proliferation (Days 4-14)

Objective: Promote endogenous ECM deposition and establish proliferative niches.

Protocol:

- Medium Shift: Transition to "Growth Medium": Stabilization Medium (without Y-27632) plus:

- Organoid-specific growth factors (e.g., 50 ng/mL EGF for colorectal, 100 ng/mL FGF-10 & Noggin for gastric).

- 1% (v/v) Matrigel for scaffolding support.

- Feeding Schedule: Perform a full medium change every 48 hours.

- Monitoring: Image daily using bright-field microscopy. Expect visible spheroid formation and perimeter smoothing by Day 7-10.

Phase III: Long-Term Maintenance & Propagation (Day 15+)

Objective: Maintain genomic and phenotypic stability over serial passages.

Protocol:

- Regular Maintenance: Continue with Growth Medium, changing every 48-72 hours.

- Passaging (every 10-14 days): a. Gently aspirate medium. b. Add 1 mL of cold Cell Recovery Solution (Corning) per construct. Incubate 30-60 min on ice to dissolve residual bioink. c. Mechanically dissociate using a P1000 pipette (10-15 strokes). d. Pass through a 40 µm cell strainer. e. Centrifuge at 300 x g for 5 min. f. Resuspend in Growth Medium + 10 µM Y-27632. Re-seed into fresh pre-warmed bioink or Matrigel droplets.

- Cryopreservation: Resuspend dissociated organoids in Recovery Medium with 10% DMSO. Cool at -1°C/min in an isopropanol chamber before transfer to liquid N2.

Validation & Functional Assessment Protocols

Rigorous validation is required to confirm tumor organoid fidelity.

Protocol: Immunofluorescence for Polarity & Lineage Markers

Fixation: 4% PFA for 45 min at RT. Permeabilization: 0.5% Triton X-100 for 20 min. Blocking: 3% BSA + 0.1% Tween-20 for 2 hours. Primary Antibodies: Incubate overnight at 4°C (e.g., E-cadherin [1:200], Ki67 [1:100], Cleaved Caspase-3 [1:150]). Secondary Antibodies: Incubate for 2 hours at RT (e.g., Alexa Fluor conjugates, 1:500). Imaging: Acquire z-stacks on a confocal microscope.

Protocol: Drug Response Assay (IC50 Determination)

- Dissociate organoids to single cells and re-embed in 50 µL Matrigel droplets (1000 cells/droplet) in a 96-well plate.

- After 72h of recovery, treat with a 10-point serial dilution of the chemotherapeutic agent (e.g., 5-FU, Oxaliplatin).

- At 96h post-treatment, add CellTiter-Glo 3D reagent and luminescence.

- Calculate IC50 values using a four-parameter logistic model in Prism GraphPad.

Table 2: Example Drug Response Data from Bioprinted CRC Organoids

| Chemotherapeutic | Average IC50 (µM) | 95% Confidence Interval | R² of Curve Fit | Reference 2D Monolayer IC50 (µM) |

|---|---|---|---|---|

| 5-Fluorouracil | 12.4 | [9.8 - 15.7] | 0.98 | 1.2 |

| Oxaliplatin | 0.85 | [0.62 - 1.16] | 0.97 | 0.15 |

| Irinotecan | 4.21 | [3.11 - 5.70] | 0.96 | 0.89 |

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Reagents for Post-Printing Maturation

| Reagent / Material | Supplier (Example) | Primary Function in Protocol |

|---|---|---|

| Y-27632 (ROCK Inhibitor) | Tocris Bioscience | Reduces anoikis and printing-induced apoptosis during acute recovery. |

| B-27 Supplement (Minus Vitamin A) | Gibco | Provides hormone and nutrient support; minus Vit A reduces differentiation. |

| Recombinant Human EGF/FGF-10/Noggin | PeproTech | Organoid-specific growth factors to maintain stemness and proliferation. |

| Growth Factor-Reduced Matrigel | Corning | Provides a temporary, supportive scaffold for ECM deposition and structure. |

| Cell Recovery Solution | Corning | Dissolves cross-linked bioink (e.g., alginate) without damaging cell-cell junctions. |

| CellTiter-Glo 3D Assay | Promega | Luminescent ATP quantitation for viability in 3D structures. |

| Advanced DMEM/F12 | Gibco | Basal medium optimized for low-serum organoid culture. |

Visualization of Key Pathways and Workflows

Title: Post-Printing Stressors and Stabilization Pathways

Title: Three-Phase Post-Printing Maturation Workflow

Three-dimensional bioprinted tumor organoids have emerged as a transformative platform for oncology research, bridging the gap between traditional 2D cell cultures and in vivo patient-derived xenografts. These constructs recapitulate the tumor microenvironment (TME), including cell-cell interactions, extracellular matrix (ECM) composition, and gradient-driven phenomena like hypoxia. This fidelity makes them ideal for two frontier applications: high-throughput drug screening (HTS) to accelerate drug discovery, and immunotherapy testing to evaluate novel immune-oncology agents such as immune checkpoint inhibitors (ICIs), bispecific T-cell engagers (BiTEs), and CAR-T cells. This document provides detailed application notes and standardized protocols for implementing these assays using bioprinted tumor organoids.

Application Note: High-Throughput Drug Screening (HTS)

Objective: To utilize bioprinted tumor organoids for the rapid, reproducible evaluation of compound libraries, assessing efficacy, toxicity, and mechanism of action.

Key Advantages Over 2D Models:

- Physiological Relevance: 3D architecture influences drug penetration, cell survival signaling, and resistance mechanisms.

- Stromal Integration: Co-printing with cancer-associated fibroblasts (CAFs) and endothelial cells models stromal protection.

- High-Content Readouts: Enables multiplexed endpoint analysis (viability, apoptosis, proliferation).

Quantitative Data Summary: Table 1: Comparison of Drug Screening Platforms