CAR-T Cell Engineering and Manufacturing Protocols: From Foundational Concepts to Advanced Clinical Applications

This article provides a comprehensive overview of the current landscape of Chimeric Antigen Receptor (CAR)-T cell engineering and manufacturing.

CAR-T Cell Engineering and Manufacturing Protocols: From Foundational Concepts to Advanced Clinical Applications

Abstract

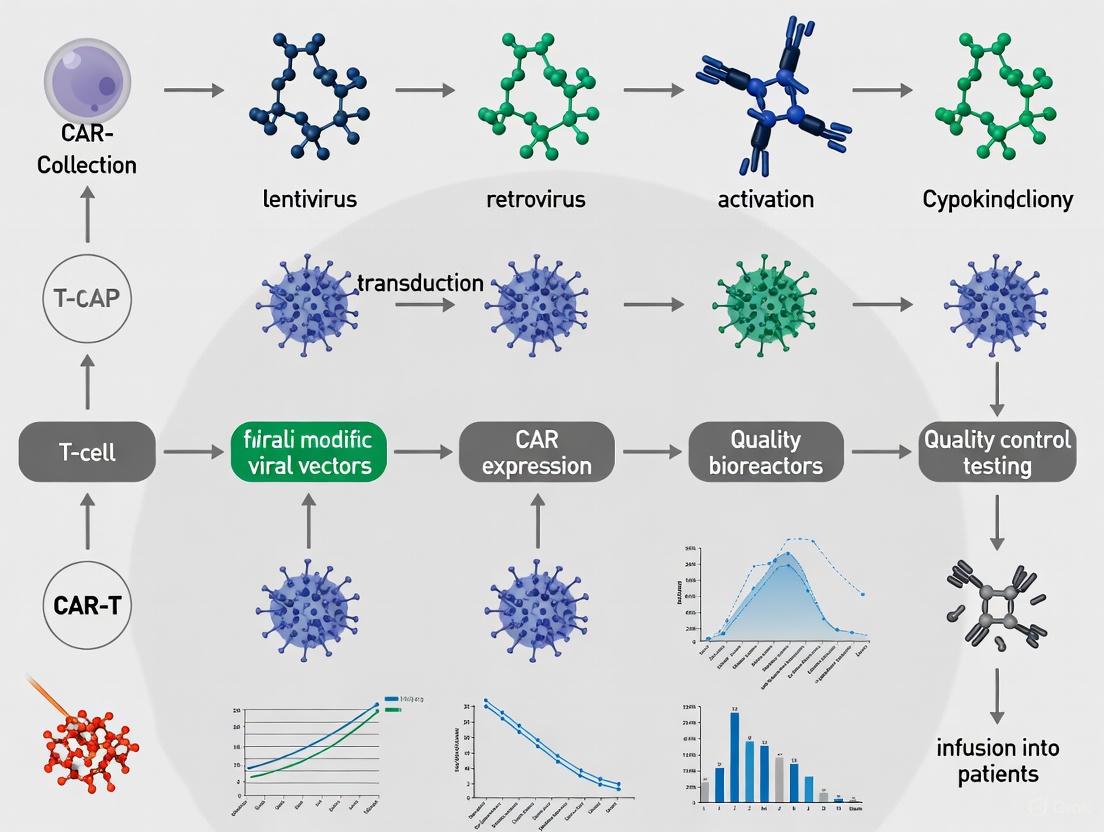

This article provides a comprehensive overview of the current landscape of Chimeric Antigen Receptor (CAR)-T cell engineering and manufacturing. It explores the foundational principles of CAR design, from first to next-generation constructs, and details established and emerging manufacturing protocols, including ex vivo and innovative in vivo approaches. The content delves into critical challenges such as resistance mechanisms, manufacturing bottlenecks, and high costs, while presenting optimization strategies involving process automation, cryopreservation, and decentralized models. Furthermore, it examines advanced validation techniques, including multi-omics potency assays and real-world data utilization, for ensuring product quality and efficacy. Aimed at researchers, scientists, and drug development professionals, this review synthesizes recent advances to guide the future development of more accessible, potent, and safe CAR-T cell therapies.

Deconstructing CAR Architecture and Immune Cell Engineering Fundamentals

Chimeric Antigen Receptors (CARs) are synthetic receptors that reprogram immune effector cells, most commonly T cells, to recognize and eliminate cancer cells with specified antigen specificity. The modular architecture of a CAR is fundamental to its function, consisting of three core domains: an ectodomain responsible for antigen recognition, a transmembrane domain that anchors the receptor to the cell membrane, and an endodomain that initiates intracellular signaling for T cell activation [1] [2]. This application note delineates the structure-function relationships of these domains, provides detailed protocols for their experimental evaluation, and synthesizes quantitative data to guide researchers in the rational design of novel CAR constructs.

The Structural and Functional Anatomy of CAR Domains

Ectodomain: The Antigen Recognition Module

The ectodomain is the variable region of the CAR that extends into the extracellular space and is responsible for binding the target antigen on tumor cells. Its design is critical for determining specificity, affinity, and the stability of the receptor [3] [2].

- Antigen Recognition Domain: The most common antigen-binding moiety is a single-chain variable fragment (scFv) derived from monoclonal antibodies. An scFv is a fusion protein of the variable regions of the immunoglobulin heavy (VH) and light (VL) chains, connected by a short, flexible peptide linker [1] [4]. Alternative binding domains include camelid nanobodies, natural ligands, or peptides [3].

- Linker Region: The linker that connects the VH and VL chains influences scFv stability and aggregation propensity. Common linkers include the (G4S)n repeats (e.g., (G4S)3 or (G4S)4) and the Whitlow linker (GSTSGSGKPGSGEGSTKG) [3].

- Hinge/Spacer Domain: This region connects the antigen-binding domain to the transmembrane domain, providing flexibility and steric access to the target epitope. The length and identity of the hinge (e.g., derived from CD8α, CD28, or IgG Fc regions) profoundly impact CAR signaling strength, potency, and its ability to interact with costimulatory molecules like endogenous CD28 [3].

Table 1: Common Components of the CAR Ectodomain

| Component | Common Variants | Key Function | Design Considerations |

|---|---|---|---|

| Antigen Recognition Domain | scFv, Nanobody, Ligand | Binds target antigen on tumor cell | Specificity and affinity are paramount to avoid on-target/off-tumor toxicity [1]. |

| Linker | (G4S)3, (G4S)4, Whitlow linker | Covalently links VH and VL chains in an scFv | Length and composition affect stability and can promote dimerization ("diabody" formation) with shorter linkers, potentially enhancing avidity [3]. |

| Hinge/Spacer | CD8α, CD28, IgG1-Fc | Provides flexibility and projects binding domain from membrane | Length must be optimized for target epitope accessibility; IgG-derived hinges can mediate unwanted Fc receptor binding [3]. |

Transmembrane Domain: The Membrane Anchor and Signaling Hub

The transmembrane (TM) domain is a hydrophobic alpha helix that anchors the CAR to the T cell membrane. Beyond this structural role, it influences CAR stability, dimerization, and interaction with endogenous signaling proteins [3] [2].

- Origin and Dimerization: TM domains are typically derived from native T-cell proteins such as CD3ζ, CD28, or CD8α. The choice of TM domain can drive homodimerization (e.g., CD28) or heterodimerization with endogenous proteins, which may augment or interfere with signaling [3]. The CD28 TM domain, for instance, can stabilize a heterodimer with the endogenous CD28 receptor, potentially enhancing costimulatory signaling [3].

- Stability and Expression: The TM domain contributes to the overall stability and expression level of the CAR on the T cell surface. The CD28 transmembrane domain is reported to form one of the most stable receptors [2].

Endodomain: The Intracellular Signaling Engine

The endodomain, residing in the cytoplasm, is the signaling core of the CAR and is responsible for T cell activation upon antigen engagement. The evolution of CARs is classified into generations based on the complexity of this domain [1] [2] [4].

- First Generation: Contains only the CD3ζ chain, which bears three Immunoreceptor Tyrosine-Based Activation Motifs (ITAMs). These CARs provided initial activation signal but exhibited poor persistence and efficacy in vivo due to the lack of costimulation [2] [4].

- Second Generation: Incorporates one costimulatory domain (e.g., CD28 or 4-1BB) proximal to the CD3ζ chain. This addition significantly enhances T cell proliferation, cytokine production, cytotoxicity, and in vivo persistence [1] [4]. The choice of costimulatory domain impacts the metabolic programming and persistence of CAR-T cells; CD28 domains promote potent effector functions, while 4-1BB domains favor a memory-like phenotype and longer persistence [4].

- Third Generation: Combines two or more different costimulatory domains (e.g., CD28 combined with 4-1BB or OX40) within the same endodomain, aiming to further amplify signaling and potency [1] [2].

- Fourth Generation (TRUCKs): These are second-generation CARs further engineered to inducibly express transgenic immune modifiers, such as cytokines (e.g., IL-12), upon CAR signaling. This recruits and activates innate immune cells to modify the tumor microenvironment [1] [2].

- Fifth Generation: These next-generation constructs incorporate additional signaling pathways, such as the IL-2 receptor beta chain (IL-2Rβ) with a STAT3/5 binding motif, to further promote T cell growth, memory formation, and prevent exhaustion [1].

Table 2: Evolution of CAR Endodomains and Their Functional Outcomes

| CAR Generation | Signaling Domains | Key Functional Characteristics | Clinical & Preclinical Notes |

|---|---|---|---|

| First | CD3ζ | Limited persistence, short in vivo lifespan, requires exogenous cytokines [2]. | Superseded in clinical practice due to limited efficacy. |

| Second | CD3ζ + CD28 | Potent, rapid effector response; may promote terminal differentiation and activation-induced cell death [4]. | Used in approved products (Axi-cel, Brexu-cel). |

| Second | CD3ζ + 4-1BB | Enhanced persistence, slower but sustained activation; favors a memory-like phenotype [4]. | Used in approved products (Tisa-cel, Liso-cel, Cilta-cel). |

| Third | CD3ζ + CD28 + 4-1BB (or OX40) | Augmented cytokine production and killing ability; signaling complexity requires careful optimization [1] [2]. | Not yet superior to 2nd gen in approved therapies; under investigation. |

| Fourth (TRUCK) | CD3ζ + Costim + Cytokine transgene | Enables in-situ modification of the tumor microenvironment; can recruit innate immunity [1] [2]. | Preclinical and early clinical trials for solid tumors. |

| Fifth | CD3ζ + Costim + JAK/STAT motif | Enables antigen-dependent cytokine signaling (e.g., via IL-2Rβ) to enhance persistence and prevent exhaustion [1]. | Next-generation platforms in preclinical development. |

Visualization of CAR-T Cell Signaling Pathway

The diagram below illustrates the core signaling pathway initiated upon antigen binding to a second-generation CAR, leading to T cell activation and effector functions.

CAR Signaling Pathway - Antigen binding induces CAR clustering, triggering an intracellular signaling cascade that results in T cell effector functions.

Detailed Experimental Protocol for CAR-T Cell Generation and Evaluation

This protocol outlines a standardized methodology for producing and functionally validating CAR-T cells, incorporating both manual and semi-automated processes [5] [6].

T Cell Isolation and Activation

- Objective: To isolate a pure population of human T cells and activate them for genetic modification.

- Materials:

- Leukapheresis Product: Obtained from healthy donor or patient.

- Ficoll-Paque PLUS: For density gradient centrifugation.

- Phosphate-Buffered Saline (PBS) + 1-2% Human Serum Albumin (HSA).

- T Cell Activation Beads: e.g., anti-CD3/CD28 magnetic beads.

- Cell Culture Media: X-VIVO 15 or RPMI-1640, supplemented with 5-10% Fetal Bovine Serum (FBS) or human AB serum, and L-glutamine.

- Procedure:

- Isolate Peripheral Blood Mononuclear Cells (PBMCs) from the leukapheresis product using Ficoll density gradient centrifugation.

- Wash PBMCs twice with PBS/HSA.

- Isolate T cells from PBMCs using a negative selection magnetic bead kit per manufacturer's instructions.

- Resuspend T cells in pre-warmed culture media at a concentration of 1-2 x 10^6 cells/mL.

- Add anti-CD3/CD28 beads at a bead-to-cell ratio of 1:1 to 3:1.

- Incubate cells at 37°C, 5% CO2 for 24-48 hours.

Genetic Modification with CAR Construct

- Objective: To introduce the CAR gene into activated T cells.

- Materials:

- CAR Transgene: Delivered via lentiviral/retroviral vector or as a CRISPR/Cas9 ribonucleoprotein (RNP) complex for targeted integration [5].

- Transduction Enhancer: e.g., Retronectin, Protamine Sulfate.

- Electroporation Device: e.g., Lonza 4D-Nucleofector (for non-viral methods).

- Procedure A - Viral Transduction:

- After 24 hours of activation, harvest T cells and resuspend in fresh media at 1-2 x 10^6 cells/mL.

- Pre-load non-tissue culture treated plates with retronectin (10-20 µg/mL) and the viral supernatant containing the CAR construct (Multiplicity of Infection, MOI 3-10).

- Centrifuge the plate to facilitate viral attachment (e.g., 2000 x g, 90 min, 32°C).

- Aspirate supernatant and seed activated T cells onto the viral-coated plates.

- Centrifuge again (e.g., 1000 x g, 30 min, 32°C).

- Incubate at 37°C, 5% CO2 for 24 hours before replacing with fresh media.

- Procedure B - Non-Viral Electroporation (e.g., CRISPR/Cas9):

- Pre-complex CRISPR/Cas9 RNP with a DNA donor template carrying the CAR gene.

- Wash activated T cells and resuspend in appropriate electroporation buffer.

- Mix cells with the RNP/donor complex and electroporate using a pre-optimized program (e.g., EO-115 on Lonza 4D-Nucleofector).

- Immediately transfer cells to pre-warmed media and incubate.

Cell Expansion and Formulation

- Objective: To expand the genetically modified T cells to a clinically relevant dose.

- Materials:

- Cell Culture Bioreactor: T-flasks, G-Rex bags, or automated systems like the Cocoon or CliniMACS Prodigy [6].

- Recombinant Human IL-2 or IL-7/IL-15.

- Procedure:

- After transduction/electroporation, maintain cells in culture media supplemented with cytokines (e.g., IL-2 at 50-100 IU/mL).

- Monitor cell density and split cultures as needed to maintain 0.5-1.5 x 10^6 cells/mL.

- Expand cells for 7-14 days, until the target cell number is achieved (e.g., 1-5 x 10^8 CAR+ T cells).

- Harvest cells, wash, and formulate in infusion medium (e.g., CryoStor CS10 for cryopreservation).

Quality Control and Functional Validation

- Objective: To assess the quality, phenotype, and cytotoxic function of the final CAR-T cell product.

- Materials:

- Flow Cytometer.

- Antibodies: For CAR detection (e.g., anti-linker or anti-Fab antibodies), T cell markers (CD3, CD4, CD8), activation markers (CD25, CD69), and exhaustion markers (PD-1, LAG-3, TIM-3).

- Target Tumor Cell Line: e.g., NALM6 (for CD19-CAR).

- Cytokine Detection Kit: e.g., ELISA or LEGENDplex for IFN-γ, IL-2, TNF-α.

- Procedure:

- CAR Expression & Phenotype: Stain CAR-T cells with relevant antibodies and analyze by flow cytometry. Report the percentage of CAR+ T cells and memory/effector subsets.

- In Vitro Cytotoxicity:

- Co-culture CAR-T cells with fluorescently labeled target tumor cells at various Effector:Target (E:T) ratios (e.g., 1:1 to 20:1) for 12-24 hours.

- Measure specific lysis using a real-time cell analyzer (e.g., xCelligence) or by flow cytometry using a viability dye.

- Cytokine Release:

- Co-culture CAR-T cells with target cells at a set E:T ratio (e.g., 1:1) for 24 hours.

- Collect supernatant and quantify cytokine levels via ELISA.

- Persistence & Exhaustion: Perform longitudinal assays to monitor CAR-T cell survival and the upregulation of exhaustion markers upon repeated antigen stimulation.

The Scientist's Toolkit: Essential Research Reagents

Table 3: Key Reagents for CAR-T Cell Research and Development

| Reagent/Category | Specific Examples | Primary Function in CAR-T Workflow |

|---|---|---|

| T Cell Isolation | CD3/CD28 Activation Beads, Pan T Cell Isolation Kit (human) | Isulates and activates T cells from PBMCs, initiating proliferation. |

| Gene Delivery | Lentiviral Vectors, Retroviral Vectors, CRISPR-Cas9 RNP | Introduces the CAR genetic construct into the T cell genome. |

| CAR Detection | Anti-mouse Fab-Fragment Antibodies, Labeled Antigen Recombinant Protein | Detects and quantifies surface expression of the CAR via flow cytometry. |

| Cell Culture Media | X-VIVO 15, TexMACS, RPMI-1640 | Provides nutrients and environment for T cell expansion and maintenance. |

| Cytokines | Recombinant Human IL-2, IL-7, IL-15 | Supports T cell survival, growth, and can influence differentiation during culture. |

| Flow Cytometry Antibodies | Anti-human CD3, CD4, CD8, CD45RA, CD62L, PD-1, TIM-3 | Characterizes T cell phenotype, memory subsets, and activation/exhaustion status. |

| Target Cell Lines | NALM6 (CD19+), K562 (often engineered to express target antigen) | Serves as target cells for in vitro functional assays (killing, cytokine release). |

Advanced Engineering and Future Perspectives

The field is rapidly advancing beyond the standard second-generation CAR to address challenges in solid tumors, toxicity, and manufacturing. Key innovations include:

- Logic-Gated CARs: Systems like the TME-gated inducible CAR (TME-iCAR) require multiple inputs (e.g., tumor antigen + hypoxia + small molecule inducer) for activation, enhancing tumor specificity and safety [7].

- Universal Off-the-Shelf CAR-T (UCAR-T): Derived from healthy donors, these aim to overcome patient-specific manufacturing delays. They require gene editing (e.g., CRISPR/Cas9-mediated TRAC locus disruption) to prevent Graft-versus-Host Disease (GvHD) and Host-versus-Graft Rejection (HvGR) [8].

- Automated Manufacturing: Platforms like the CliniMACS Prodigy and Cocoon enable semi-automated, closed-system manufacturing, which reduces variability, improves scalability, and shortens vein-to-vein time for patients [5] [6] [9].

In conclusion, a deep understanding of the modular blueprint of CARs—from ectodomain fine-tuning to endodomain signaling logic—is the foundation for designing the next generation of safer and more effective cellular immunotherapies. The protocols and data summarized herein provide a framework for systematic research and development in this dynamic field.

Chimeric Antigen Receptor (CAR)-T cell therapy represents a transformative breakthrough in cancer immunotherapy, harnessing the adaptive immune system to selectively eradicate cancer cells [10] [4]. This approach involves genetically engineering a patient's own T cells to express synthetic receptors that redirect their specificity toward tumor-associated antigens in a non-MHC-restricted manner [11]. The clinical success of CAR-T cell therapy, particularly for hematological malignancies, is a direct result of continuous refinements in CAR architecture [12]. These synthetic receptors have evolved from early prototypes with limited therapeutic efficacy to advanced next-generation constructs incorporating co-stimulatory domains, cytokine signaling, safety switches, and precision control mechanisms [10]. This evolution has markedly enhanced the persistence, antitumor activity, and safety profiles of CAR-T cells [4]. Understanding this developmental trajectory is essential for researchers and drug development professionals working to expand the applicability of CAR therapy to various cancer types and potentially other diseases [12].

Structural Foundations of CAR Design

The fundamental architecture of CARs consists of three core domains: an ectodomain, a transmembrane domain, and an endodomain [11]. This modular structure has remained consistent throughout the evolution of CAR designs, with refinements primarily focusing on the intracellular signaling components to enhance functional outcomes.

Core Structural Components

Ectodomain: This extracellular component contains the antigen recognition domain, typically a single-chain variable fragment (scFv) derived from monoclonal antibodies, and a hinge or spacer region that provides flexibility and access to target epitopes [11]. The scFv is formed from the variable regions of the light (VL) and heavy (VH) chains of an antibody, conferring CAR specificity toward target antigens independent of HLA presentation [11].

Transmembrane Domain: A lipophilic alpha-helical domain that anchors the CAR to the T cell membrane, facilitates stable receptor expression, and influences CAR signaling through potential interactions with endogenous membrane proteins [11]. Common sources for this domain include CD4, CD8α, CD28, or CD3ζ [11].

Endodomain: The intracellular signaling component that initiates T cell activation upon antigen recognition [11]. The primary functional unit is the CD3ζ chain from the TCR complex, which contains three immunoreceptor tyrosine-based activation motifs (ITAMs) essential for signal transduction [11] [13].

Table 1: Fundamental Structural Components of CAR Constructs

| Domain | Key Elements | Function | Common Sources |

|---|---|---|---|

| Ectodomain | Antigen recognition domain (scFv), Hinge region | Target antigen recognition, Binding specificity | Murine/humanized antibodies, Engineered binding scaffolds |

| Transmembrane Domain | Hydrophobic alpha-helix | Membrane anchoring, Receptor stability | CD4, CD8α, CD28, CD3ζ |

| Endodomain | Signaling domains (CD3ζ, co-stimulatory) | T cell activation, Cytokine production, Proliferation | CD3ζ, CD28, 4-1BB, OX40 |

The Generational Evolution of CAR Designs

First-Generation CARs

First-generation (1G) CARs, developed in 1993, consisted of a scFv fused directly to a single intracellular T cell receptor signaling domain, most often CD3ζ or, in some early studies, the Fc receptor gamma chain (FcγR) [10] [4]. These pioneering constructs were designed to utilize T cell cytotoxic effects with antibody-like specificity while bypassing MHC restriction [10].

Experimental Protocol: Evaluation of First-Generation CAR Function

- CAR Construction: Amplify VL and VH regions from hybridoma cells producing target-specific monoclonal antibodies. Assemble scFv using (Gly₄Ser)₃ linker and fuse with CD3ζ signaling domain via overlap extension PCR [10].

- Vector Assembly: Clone CAR cassette into gamma-retroviral or lentiviral transfer plasmid under control of EF-1α or CMV promoter.

- T Cell Transduction: Isolate PBMCs from leukapheresis product via Ficoll density gradient. Activate T cells with anti-CD3/CD28 beads and culture in IL-2 supplemented media. Transduce activated T cells using retroviral transduction protocols [10].

- Functional Assessment:

- Evaluate cytotoxicity via ⁵¹Cr release assay against target-positive and target-negative cell lines.

- Measure cytokine production (IFN-γ, IL-2) by ELISA after 24-hour co-culture with antigen-expressing cells.

- Assess in vivo efficacy in immunodeficient mice bearing subcutaneous tumor xenografts [10].

Despite promising in vitro results, 1G CARs demonstrated limited clinical efficacy in early trials due to the absence of co-stimulatory signals, resulting in poor in vivo persistence and failure to maintain long-term antitumor responses [10] [13]. Additionally, these early clinical trials highlighted the risk of severe side effects, such as cytokine release syndrome (CRS), necessitating adjustments to CAR design and safety mechanisms [10].

Second-Generation CARs

To address the limitations of 1G CARs, second-generation (2G) constructs incorporated one additional co-stimulatory domain alongside the CD3ζ signaling domain [10] [4]. This design innovation was based on the understanding that natural T cell activation requires two signals: (1) antigen recognition through the TCR, and (2) co-stimulation through receptors such as CD28 interacting with their ligands on antigen-presenting cells [10].

Diagram Title: Second-Generation CAR Structure

CD28 and 4-1BB (CD137) emerged as the most commonly used co-stimulatory domains in 2G CARs, with each imparting distinct functional characteristics [10]. CD28 domains promote rapid tumor elimination through enhanced IL-2 production and metabolic reprogramming, while 4-1BB domains favor longer persistence in circulation through reduced exhaustion and increased mitochondrial biogenesis [13]. The notable clinical success of CD19-redirected 2G CAR-T cell therapy in treating B-cell malignancies led to the first FDA approvals in 2017, including Kymriah (tisagenlecleucel) and Yescarta (axicabtagene ciloleucel) [10] [4].

Experimental Protocol: Comparing Co-stimulatory Domain Function

- Construct Generation: Create identical CAR constructs differing only in co-stimulatory domains (CD28 vs. 4-1BB) using isothermal assembly. Verify sequence integrity by Sanger sequencing.

- T Cell Manufacturing: Isolate naive and memory T cell subsets via magnetic bead separation. Transduce subsets separately, then combine CD4+ and CD8+ CAR-T cells at defined ratios (e.g., 1:1) [11].

- Metabolic Profiling:

- Analyze mitochondrial content via MitoTracker staining and flow cytometry.

- Measure extracellular acidification rate (ECAR) and oxygen consumption rate (OCR) using Seahorse Analyzer.

- Assess nutrient uptake through glucose and glutamine consumption assays.

- Persistence Studies:

Table 2: Comparison of Second-Generation CAR Co-stimulatory Domains

| Parameter | CD28-Based CARs | 4-1BB-Based CARs |

|---|---|---|

| Signaling Pathway | PI3K/Akt | TRAF2/NF-κB |

| Metabolic Profile | Glycolytic metabolism | Oxidative phosphorylation |

| In Vivo Persistence | Shorter (weeks to months) | Longer (months to years) |

| Cytokine Production | High IL-2, IFN-γ | Moderate IL-2, IFN-γ |

| Clinical Expansion | Robust initial expansion | Sustained lower-level expansion |

| Exhaustion Profile | Higher exhaustion markers | Reduced exhaustion |

| Representative Product | Yescarta | Kymriah |

Third-Generation CARs

Third-generation (3G) CARs incorporate multiple co-stimulatory signaling domains within the endodomain to further enhance T cell activation and persistence [13]. Common configurations include CD3ζ-CD28-OX40 or CD3ζ-CD28-41BB combinations, designed to synergistically activate multiple signaling pathways simultaneously [13].

Experimental Protocol: Assessing Synergistic Signaling

- Multisignal Validation:

- Generate 3G CARs with CD3ζ plus two co-stimulatory domains in varying orientations.

- Assess phosphorylation events via phospho-flow cytometry 15 minutes after antigen stimulation.

- Perform Western blotting for key signaling nodes (ERK, AKT, NF-κB) at 0, 5, 15, 30, and 60 minutes post-stimulation. III- Functional Multiplexing:

- Measure NF-κB and NFAT activation using dual-reporter assays (luciferase/GFP).

- Evaluate resistance to exhaustion through repeated antigen stimulation cycles (3-5 rounds, 7-day intervals).

- Compare transcriptomic profiles via RNA-seq of 2G vs. 3G CAR-T cells after antigen exposure [13].

Despite theoretical advantages, third-generation CARs have not consistently demonstrated enhanced efficacy compared to second-generation constructs in clinical settings, though they maintain favorable safety profiles and improved persistence characteristics [13].

Fourth-Generation CARs (TRUCKs)

Fourth-generation CARs, termed T cells Redirected for Universal Cytokine-Mediated Killing (TRUCKs), are based on second-generation constructs but incorporate an inducible cytokine expression cassette [13]. These designs typically utilize a nuclear factor of activated T cells (NFAT)-responsive promoter to drive transgenic cytokine expression (e.g., IL-12, IL-18) specifically upon CAR engagement with its target [13].

Diagram Title: Fourth-Generation TRUCK CAR Mechanism

Experimental Protocol: TRUCK CAR Engineering and Validation

- Inducible Cassette Design:

- Clone NFAT-responsive element (4xNFAT) upstream of cytokine gene in lentiviral vector.

- Incorporate CAR expression cassette with P2A self-cleaving peptide separated from cytokine module.

- Validate promoter specificity by stimulating with target-positive vs. target-negative cells.

- Conditional Cytokine Measurement:

- Co-culture TRUCK CAR-T cells with target cells for 24-48 hours.

- Measure cytokine secretion in supernatant via multiplex Luminex assay.

- Assess bystander immune cell recruitment in 3D tumor spheroid co-cultures.

- Tumor Microenvironment Modulation:

- Evaluate CAR-T cell infiltration and function in patient-derived xenograft (PDX) models.

- Analyze myeloid cell polarization (M1 vs. M2 macrophages) in tumor samples.

- Monitor systemic vs. localized cytokine levels to assess safety profile [13].

In preclinical models, TRUCK CARs demonstrated enhanced efficacy compared to second-generation CARs, particularly against solid tumors, while avoiding systemic toxicity through localized cytokine delivery [13].

Fifth-Generation CARs

Fifth-generation CARs represent the cutting edge of CAR design, integrating additional membrane receptor components, most commonly truncated cytokine receptors (e.g., IL-2 receptor β chain) that allow JAK-STAT signaling activation in an antigen-dependent manner [13]. These constructs aim to provide more complete T cell activation signals while maintaining precise control over therapeutic activity.

Key Advancements:

- Cytceptor Designs: Incorporation of cytokine receptor domains that activate JAK-STAT signaling upon CAR engagement, promoting T cell expansion and persistence while reducing exhaustion [13].

- Molecular Switches: Implementation of drug-dependent ON- and OFF-switches, such as lenalidomide-gated CARs, that enable precise temporal control over CAR activity for improved safety profiles [13].

- Universal CAR Platforms: Development of split, universal, and programmable CAR systems that separate targeting from signaling domains, allowing for flexible antigen targeting without re-engineering T cells [10].

Experimental Protocol: Controllable CAR Systems

- Switchable CAR Engineering:

- Fuse CAR signaling domain to drug-binding domain (e.g., FKBP12F⁷V).

- Generate separate targeting module with scFv fused to drug-binding partner.

- Titrate bridging molecule (e.g., rimiducid) to optimize ON/OFF kinetics.

- Kinetic Control Assessment:

- Measure CAR activation kinetics after drug administration in vitro.

- Evaluate reversibility by washing out drug and monitoring CAR deactivation.

- Determine therapeutic window in xenogeneic tumor models with dose-ranging studies.

- Safety Profiling:

- Assess on-target/off-tumor toxicity in human tissue cross-reactivity models.

- Test cytokine release syndrome potential in humanized mouse models.

- Evaluate maximum tolerable dose and therapeutic index in preclinical models [13].

Table 3: Progression of CAR Generations and Their Characteristics

| Generation | Intracellular Domains | Key Features | Advantages | Limitations |

|---|---|---|---|---|

| First | CD3ζ only | MHC-independent recognition | Simple design | Limited persistence, No co-stimulation |

| Second | CD3ζ + 1 co-stimulatory | One co-stimulatory signal | Enhanced persistence, Improved efficacy | Potential exhaustion, Limited solid tumor activity |

| Third | CD3ζ + 2 co-stimulatory | Multiple co-stimulatory signals | Synergistic signaling | Increased complexity, Unclear clinical benefit |

| Fourth (TRUCK) | CD3ζ + 1 co-stim + inducible cytokine | Inducible cytokine secretion | Modifies tumor microenvironment, Recruits innate immunity | Cytokine-related toxicity risk |

| Fifth | CD3ζ + 1 co-stim + cytokine receptor | JAK-STAT activation | Enhanced persistence, Reduced exhaustion, Controllable activity | Complex engineering, Immunogenicity concerns |

Emerging Technologies and Future Directions

Advanced Gene Editing Applications

Emergent genetic engineering tools, including CRISPR/Cas9, base editing, prime editing, and RNA/epigenome editing, hold significant promise for enhancing CAR-T cell function and safety [10] [4]. These technologies enable precise genomic modifications that can reduce immunogenicity, minimize graft-versus-host disease (GVHD) risk in allogeneic settings, and disrupt endogenous TCR expression to prevent mispairing [10].

Experimental Protocol: CRISPR-Mediated CAR Integration

- Target Site Selection: Identify genomic safe harbor loci (AAVS1, CCR5, TRAC) via bioinformatic analysis.

- gRNA Design and Validation: Design guide RNAs with minimal off-target potential using in silico prediction tools. Validate cleavage efficiency via T7E1 assay or next-generation sequencing.

- Multiplexed Editing: Co-electroporate Cas9 ribonucleoprotein complexes with donor template containing CAR cassette flanked by homology arms.

- Comprehensive Genotyping:

- Assess on-target integration efficiency via droplet digital PCR.

- Evaluate off-target editing through GUIDE-seq or CIRCLE-seq.

- Perform karyotypic analysis to confirm genomic stability.

- Validate TCR knockout via flow cytometry for TCRαβ and CD3 [10].

Manufacturing and Regulatory Considerations

The development of robust manufacturing processes and adherence to regulatory guidelines are critical for the successful translation of next-generation CAR-T cell therapies [14] [15]. Key considerations include maintaining quality control of starting materials, implementing comprehensive characterization assays, and ensuring lot-to-lot consistency throughout product development [14] [16].

Table 4: Essential Research Reagents for CAR-T Cell Development

| Reagent Category | Specific Examples | Research Application | Functional Role |

|---|---|---|---|

| CAR Detection | CAR Dextramer reagents, Anti-idiotype antibodies | CAR expression quantification, Binding specificity verification | Confirm CAR identity and antigen binding capability |

| Cell Isolation | Magnetic bead kits (CD3, CD4, CD8), Cytokine capture assays | T cell subset isolation, Memory cell enrichment | Define T cell population composition for manufacturing |

| Characterization | MHC Dextramer reagents, dCODE Dextramer | TCR specificity profiling, Single-cell multi-omics | Assess impact on endogenous T cell function and specificity |

| Functional Assays | Xynapse-T, Cytokine multiplex panels, Cytotoxicity assays | Potency assessment, Exhaustion profiling | Evaluate biological activity and therapeutic potential |

| Gene Editing | CRISPR/Cas9 systems, Base editors, AAV6 donor templates | Knockout of inhibitory receptors, Safe harbor integration | Enhance CAR-T cell function and persistence |

Experimental Protocol: Analytical Assay Development for Regulatory Compliance

- CAR Detection and Quantification:

- Establish flow cytometry assays using antigen-based CAR Dextramer reagents.

- Validate assay precision, accuracy, and linearity per ICH Q2(R1) guidelines.

- Determine limit of detection and quantification using serial dilutions of CAR-positive cells.

- Potency Assay Development:

- Implement multi-parameter assays measuring target cell killing, cytokine secretion, and proliferation.

- Establish release criteria based on clinical correlation data.

- Perform assay robustness testing across multiple operators and instruments.

- Comprehensive Characterization:

- Assess T cell differentiation status via CD45RA, CCR7, CD62L expression.

- Evaluate exhaustion markers (PD-1, LAG-3, TIM-3) before and after antigen stimulation.

- Perform TCR repertoire analysis via next-generation sequencing.

- Conduct viral antigen specificity testing to confirm preserved immune function [16].

The evolution of CAR designs from simple first-generation constructs to sophisticated fifth-generation systems represents a remarkable convergence of immunology, synthetic biology, and genetic engineering [10] [12]. Each generational advancement has addressed specific limitations of previous designs, culminating in CAR-T cells with enhanced persistence, superior antitumor activity, and improved safety profiles [4]. The continued refinement of CAR architectures, coupled with emerging gene editing technologies and innovative manufacturing approaches, promises to further expand the therapeutic potential of this groundbreaking modality [10]. As the field progresses toward more controllable and targeted systems, next-generation CAR-T therapies hold immense promise for overcoming current challenges in solid tumor treatment and potentially expanding into non-oncological applications, including autoimmune disorders, infectious diseases, and transplant rejection [10] [4]. For researchers and drug development professionals, understanding this evolutionary trajectory provides critical insights for designing the next wave of cellular immunotherapies that will ultimately improve patient outcomes across a spectrum of devastating diseases.

Chimeric Antigen Receptor (CAR) T-cell therapy has revolutionized the treatment of relapsed and refractory hematological malignancies. While the extracellular antigen-recognition domain dictates target specificity, the intracellular costimulatory domains are pivotal in determining the overall potency, persistence, and functional fate of CAR-T cells [1]. These domains provide the critical "second signal" required for full T-cell activation, profoundly influencing metabolic programming, differentiation, and long-term efficacy [17] [18].

All currently FDA-approved CAR-T products are second-generation constructs featuring a single costimulatory domain—either CD28 or 4-1BB—fused to the CD3ζ signaling chain [1] [19]. However, research is rapidly advancing into third-generation CARs incorporating multiple costimulatory signals (e.g., CD28/4-1BB, ICOS/4-1BB, or ICOS/OX40) to enhance complementary functionalities [20] [1]. This application note provides a structured comparison of four key costimulatory domains (CD28, 4-1BB, OX40, and ICOS), summarizes their distinct signaling pathways and functional outcomes, and presents detailed experimental protocols for evaluating their performance in CAR-T cell products.

Functional Comparison of Major Costimulatory Domains

The selection of a costimulatory domain directly impacts critical quality attributes of the final CAR-T cell product. The table below summarizes the characteristic functions and signaling pathways associated with each domain.

Table 1: Functional Characteristics of Individual Costimulatory Domains

| Costimulatory Domain | Key Signaling Pathways | Primary Functional Benefits | Associated Challenges |

|---|---|---|---|

| CD28 [18] | PI3K-AKT, GRB2-Ras, GRB2-VAV1 | Potent early activation; Enhanced cytotoxicity; Robust IL-2 production [20] [18] | Glycolytic metabolic reprogramming; Shorter persistence; Higher incidence of severe CRS/ICANS [18] |

| 4-1BB (CD137) [20] [17] | NF-κB, MAPK, PI3K-AKT | Promotes CD8+ central memory generation; Favors long-term persistence; Oxidative metabolism [20] [17] | Slower initial kinetic expansion; Potentially lower early cytotoxicity [20] |

| ICOS (CD278) [20] [17] | PI3K, NF-κB | Enhances Th1/Th17 polarization; Increases in vivo persistence; Stabilizes central memory phenotype [20] [17] | - |

| OX40 (CD134) [20] | NF-κB, PI3K-AKT | Suppresses Treg development; Sustains clonal expansion; Enhances T cell survival [20] | - |

Tandem (Third-Generation) Costimulatory Domains

To leverage the complementary advantages of individual domains, tandem (third-generation) CARs incorporating two costimulatory signals are under active investigation [20] [1]. These designs aim to create CAR-T cells with superior functionality by synergizing signaling pathways.

Table 2: Functional Benefits of Tandem Costimulatory Domains in Third-Generation CARs

| Tandem Domain Combination | Hypothesized/Observed Functional Benefits |

|---|---|

| CD28 + 4-1BB [20] [1] | Enhanced antitumor effect; improved proliferative capacity; retention of memory phenotype; reduced exhaustion [20] |

| ICOS + 4-1BB [20] [17] | Enhanced antitumor effects and increased persistence in vivo, including in solid tumor models [20] [17] |

| ICOS + OX40 [20] | Enhanced proliferative capacity after repeated challenges; long-lasting central memory phenotype; improved in vivo persistence and survival; abrogates IL-10 and Treg development [20] |

Figure 1: CAR-T Construct Architecture. Simplified structure of second and third-generation CARs, showing the placement of costimulatory domains within the intracellular module. TM: Transmembrane.

Experimental Protocol: Evaluating Novel Tandem Costimulatory Domains

The following protocol details a methodology for comparing CAR-T cells incorporating different costimulatory domains, using the evaluation of a novel ICOS.OX40ζ tandem construct as a model [20].

CAR Construct Design and Lentiviral Vector Production

Objective: To generate and package lentiviral vectors encoding CAR constructs with different costimulatory domains for T-cell transduction.

Materials:

- Plasmids: De novo synthesized CAR constructs (e.g., ROR1-targeting scFv with 4-1BBζ, CD28/4-1BBζ, ICOS/4-1BBζ, ICOS/OX40ζ) in lentiviral transfer plasmids [20].

- Packaging Cell Line: 293T cells (ATCC).

- Packaging Plasmids: VSV-G, RSV-Rev, pMDLg/pRRE.

- Transfection Reagent: Lipofectamine 2000.

- Cell Culture Media: Appropriate medium (e.g., DMEM) supplemented with Fetal Bovine Serum (FBS) and penicillin/streptomycin.

Procedure:

- Cell Seeding: Seed 293T cells in culture vessels to reach 60-80% confluency at the time of transfection.

- Transfection Complex Formation: For each CAR construct, prepare a DNA-lipid complex mixture containing:

- CAR lentiviral transfer plasmid

- VSV-G, RSV-Rev, and pMDLg/pRRE packaging plasmids

- Lipofectamine 2000 reagent in serum-free medium.

- Transfection: Incubate the DNA-lipid complex for 20 minutes, then add dropwise to the 293T cells.

- Vector Harvesting: Collect the lentivirus-containing supernatant at 48 and 72 hours post-transfection.

- Vector Concentration: Concentrate the supernatant by ultracentrifugation or using commercial concentration kits.

- Titration: Determine the viral titer (e.g., Transducing Units/mL) using a suitable method (e.g., qPCR for vector copy number or flow cytometry for functional transduction on a reporter cell line). Aliquot and store at -80°C.

CAR-T Cell Manufacturing and Transduction

Objective: To isolate, activate, and genetically modify human T-cells to express the CAR constructs.

Materials:

- Starting Material: Leukapheresis product from healthy donor (e.g., from Vitalant) [20].

- T-cell Isolation Kit: Immunomagnetic negative selection kit (e.g., against CD19, CD16, CD15, CD14, CD34, CD56, CD123, CD235a) [20].

- T-cell Activation: Dynabeads CD3/CD28.

- T-cell Medium (TCM): OpTmizer CTS medium supplemented with IL-2 (100 U/mL) and penicillin-streptomycin-glutamine.

- Lentiviral Vectors: Concentrated lentiviral preparations from section 3.1.

Procedure:

- PBMC Isolation: Isolate Peripheral Blood Mononuclear Cells (PBMCs) from the apheresis product by density gradient centrifugation.

- T-cell Isolation: Perform immunomagnetic negative selection on PBMCs to isolate untouched T-cells. Confirm purity (>95%) by flow cytometry.

- T-cell Activation: Stimulate isolated T-cells with Dynabeads CD3/CD28 at a cell-to-bead ratio of 1:3.

- Lentiviral Transduction: 24 hours post-activation, transduce activated T-cells with lentiviral vectors at a Multiplicity of Infection (MOI) of 3.0 in the presence of a transduction enhancer (e.g., protamine sulfate). Perform spinoculation if required.

- Cell Culture: Maintain cultures in TCM with IL-2. Expand cells for 10-14 days, maintaining a cell density of 0.5-1.5 x 10^6 cells/mL.

- Bead Removal: Remove CD3/CD28 beads magnetically approximately 10-14 days after activation.

- Cryopreservation: Harvest cells, cryopreserve in controlled-rate freezing medium, and store in liquid nitrogen for future assays.

In Vitro Functional Potency Assays

Objective: To comprehensively evaluate the effector function, cytokine profile, and differentiation status of generated CAR-T cells.

Materials:

- Target Cells: ROR1+ JeKo-1 (Mantle cell lymphoma) and ROR1- K562 (control) cell lines, preferably engineered to express a reporter (e.g., luciferase-ZsGreen) [20].

- Cytokine Detection: Multiplex cytokine array (e.g., Luminex) or ELISA for IFN-γ, IL-2, TNF-α, etc.

- Flow Cytometry Antibodies: Antibodies for CAR detection (e.g., F(ab')₂ anti-human IgG), T-cell phenotyping (CD4, CD8, CD45RO, CCR7, CD62L), and exhaustion markers (PD-1, TIM-3, LAG-3).

Procedure:

- Cytotoxicity Assay (Long-Term Challenge):

- Setup: Co-culture CAR-T cells with irradiated ROR1+ target cells at a specific Effector:Target (E:T) ratio.

- Stimulation: Re-stimulate weekly with fresh target cells.

- Monitoring: Monitor CAR-T cell expansion by cell counting and phenotype by flow cytometry over multiple cycles (e.g., 3-4 cycles) [20].

Cytokine Secretion Profiling:

- Stimulation: Co-culture CAR-T cells with target cells for 18-24 hours.

- Measurement: Collect supernatant and quantify secreted cytokines using a multiplex array or ELISA.

Immunophenotyping:

- Staining: Stain CAR-T cells with antibodies for memory (e.g., CD45RO, CCR7, CD62L, CD95) and exhaustion markers (PD-1, LAG-3, TIM-3).

- Analysis: Analyze by flow cytometry to identify proportions of stem cell memory (TSCM), central memory (TCM), effector memory (TEM), and exhausted subsets.

In Vivo Persistence and Efficacy Studies

Objective: To assess the anti-tumor activity and long-term persistence of CAR-T cells in an immunodeficient mouse model.

Materials:

- Animals: NSG (NOD-scid IL2Rγnull) mice.

- Tumor Model: Luciferase-expressing ROR1+ JeKo-1 cells.

Procedure:

- Tumor Engraftment: Inject mice intravenously with luciferase-expressing ROR1+ tumor cells.

- CAR-T Cell Administration: After tumor confirmation (e.g., via bioluminescent imaging), randomly group mice and treat with a single intravenous injection of CAR-T cells or untransduced T-cells (control).

- Tumor Monitoring: Monitor tumor burden weekly via bioluminescent imaging.

- Persistence Tracking: Regularly collect peripheral blood from mice and analyze by flow cytometry to quantify the presence of human CD3+ CAR+ T-cells over time.

- Survival and Endpoint Analysis: Monitor survival and at the experimental endpoint, analyze tissues (e.g., bone marrow, spleen) for tumor burden and CAR-T cell presence and phenotype.

Intracellular Signaling Pathways

The distinct functional outcomes driven by different costimulatory domains originate from their unique signaling properties. The diagram below illustrates the key pathways.

Figure 2: Core Signaling Pathways. Simplified overview of major signaling pathways initiated by CD28 versus 4-1BB/ICOS/OX40 costimulatory domains, leading to distinct functional outcomes.

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Reagents for CAR-T Costimulatory Domain Research

| Reagent/Category | Specific Examples & Functions | Experimental Application |

|---|---|---|

| CAR Construct Generation | De novo synthesized CAR genes; Lentiviral/retroviral transfer plasmids; rAAV6 for targeted integration [20] [8] | Stable expression of CAR constructs in T-cells; Targeted insertion into specific loci (e.g., TRAC) [8] |

| T-cell Isolation & Activation | Immunomagnetic beads for negative selection; Dynabeads CD3/CD28 for activation [20] [17] | Isolation of untouched T-cells; Robust initial T-cell activation prior to transduction [20] |

| Cell Culture & Expansion | OpTmizer CTS serum-free medium; Recombinant IL-2 [20] | Ex vivo T-cell expansion and maintenance; Promoting T-cell growth and viability [20] |

| Target Cell Lines | ROR1+ JeKo-1 (Mantle cell lymphoma); ROR1- K562 (Control) [20]; Lines engineered with luciferase-ZsGreen reporter [20] | In vitro cytotoxicity and challenge assays; In vivo tumor modeling and tracking via bioluminescent imaging [20] |

| Phenotyping & Detection | Flow cytometry antibodies: CD4, CD8, CD45RO, CCR7, CD62L, PD-1, TIM-3, LAG-3; F(ab')₂ anti-human IgG for CAR detection [20] [17] | Immunophenotyping for memory/exhaustion; Quantifying CAR expression and transduction efficiency [20] [17] |

| Gene Editing | CRISPR/Cas9 systems; Base Editors; ZFNs [8] | Generating universal CAR-T cells by knocking out TRAC and B2M [8] |

While Chimeric Antigen Receptor (CAR)-T cell therapy has revolutionized the treatment of hematological malignancies, its translation to solid tumors has been constrained by significant biological barriers. These include the immunosuppressive tumor microenvironment (TME), antigen heterogeneity, inefficient trafficking and infiltration, and poor persistence of CAR-T cells within the tumor mass [21] [22] [23]. In response, the field of cellular immunotherapy has expanded its arsenal to harness innate immune cells, leading to the emergence of CAR-Natural Killer (CAR-NK) cells and CAR-Macrophages (CAR-M) as promising alternative platforms [21] [24]. These effector cells offer distinct mechanistic advantages and are poised to overcome the unique challenges posed by solid tumors.

CAR-NK cells combine the targeted specificity of a CAR with the innate, MHC-unrestricted cytotoxicity of NK cells, enabling them to target tumors that evade adaptive immunity [21] [24]. They exhibit a favorable safety profile with a reduced risk of severe cytokine release syndrome (CRS), immune effector cell-associated neurotoxicity syndrome (ICANS), and graft-versus-host disease (GvHD), facilitating the development of "off-the-shelf" allogeneic therapies [24] [22]. Conversely, CAR-M therapies leverage the innate capacity of macrophages to infiltrate tumors, phagocytose target cells, and remodel the TME through pro-inflammatory cytokine secretion and antigen presentation to adaptive immune cells [21] [24]. This Application Note provides a detailed overview of the latest advances and standardized protocols for the engineering and functional assessment of these novel therapeutic platforms.

Recent Advances and Key Signaling Mechanisms

CAR-NK Cell Engineering Innovations

Substantial progress has been made between 2023 and 2025 to enhance the efficacy of CAR-NK cells. Key innovations focus on optimizing intracellular signaling and creating scalable cell sources.

- Lineage-Specific Signaling Domains: Unlike T-cells, NK cells respond robustly to signaling via adaptor proteins like DAP12, DAP10, 2B4 (CD244), and DNAM-1 (CD226). CAR constructs incorporating these domains, rather than canonical CD3ζ or CD28, demonstrate superior degranulation, IFN-γ production, and persistence [21]. For instance, an anti-mesothelin CAR-NK cell incorporating 2B4 and NKG2D domains showed significantly enhanced cytotoxicity against ovarian cancer models compared to T-cell-based CARs [21].

- Enhanced Cytotoxicity with NKG7: Overexpression of Natural Killer Granule Protein 7 (NKG7), a cytolytic effector molecule, has been shown to enhance IL-2 production, sustain surface CAR expression, and improve the cytotoxic activity of CAR-engineered cells against solid tumor cell lines [21].

- Induced Pluripotent Stem Cell (iPSC) Platforms: The generation of CAR-NK cells from iPSCs offers a homogeneous, renewable, and scalable "off-the-shelf" source [21]. These iNKs can be genetically engineered at early developmental stages to integrate synthetic enhancements such as chemokine receptors (e.g., CXCR2, CCR7) to improve tumor trafficking or cytokine support systems to enhance survival in the TME [21].

CAR-Macrophage Engineering Strategies

CAR-M engineering aims to create potent phagocytes that can simultaneously destroy tumors and reprogram the immunosuppressive TME.

- Pro-inflammatory Reprogramming: A key function of CAR-M is their ability to reshape the TME. Upon CAR activation, these cells shift from a immunosuppressive M2-like phenotype to a pro-inflammatory M1-like state, characterized by the secretion of cytokines such as IL-12, TNF-α, and IFN-γ, which can reverse TME-driven immune evasion [21] [24].

- Phagocytosis and Antigen Presentation: The primary cytotoxic mechanism of CAR-M is phagocytosis, a process distinct from the perforin/granzyme-mediated killing of T and NK cells [22]. Furthermore, CAR-M can process and present tumor-associated antigens to T cells, potentially initiating and sustaining a broader adaptive immune response [24].

- Early Clinical Translation: Early-phase clinical studies, such as the CT-0508 trial, have demonstrated the feasibility and safety of CAR-M therapies and their capacity to remodel the TME in patients [21].

The diagram below illustrates the core intracellular signaling pathways activated in CAR-NK and CAR-M cells upon antigen engagement, highlighting the key differences that drive their distinct effector functions.

Application Notes & Experimental Protocols

Protocol 1: Engineering and Expansion of CAR-NK Cells from Primary Isolates

This protocol details the generation of CAR-NK cells using non-viral mRNA electroporation of primary human NK cells, a method that ensures high transfection efficiency and minimizes safety concerns associated with viral vectors [25].

3.1.1 Materials and Reagents

- Source Material: Peripheral blood mononuclear cells (PBMCs) from healthy donors or cryopreserved PBMCs.

- NK Cell Isolation Kit: Human NK Cell Isolation Kit (e.g., Miltenyi Biotec).

- Culture Media: X-VIVO 15 or RPMI-1640, supplemented with 10% heat-inactivated human AB serum, 100 U/mL penicillin, 100 µg/mL streptomycin, and 2 mM L-glutamine.

- NK Cell Activation: Recombinant human IL-2 (500 U/mL) and IL-15 (10 ng/mL).

- Feeder Cells: Irradiated K562-derived feeder cells expressing membrane-bound IL-21 (e.g., K562-mbIL21-41BBL).

- CAR mRNA: In vitro transcribed mRNA encoding the CAR construct of interest, with optimized codons for NK cells and including lineage-specific signaling domains (e.g., 2B4, DAP12). The mRNA should be purified and capped.

- Electroporation System: Neon Transfection System (Thermo Fisher) or similar.

- Electroporation Buffer: Proprietary buffer provided with the electroporation system.

3.1.2 Step-by-Step Procedure

- NK Cell Isolation and Activation:

- Isolate NK cells from PBMCs using the negative selection NK Cell Isolation Kit according to the manufacturer's instructions.

- Count the cells and resuspend them in complete culture media at a concentration of 1-2 x 10^6 cells/mL.

- Add recombinant human IL-2 (500 U/mL) and IL-15 (10 ng/mL). Optionally, add irradiated feeder cells at a 1:2 (feeder:NK) ratio to enhance expansion.

- Culture the cells for 3-5 days at 37°C and 5% CO2 to pre-activate and initiate expansion.

- CAR mRNA Electroporation:

- On day 4 or 5 of culture, harvest NK cells and wash twice with 1X PBS.

- Resuspend the cell pellet in the provided electroporation buffer at a concentration of 1 x 10^7 cells/mL.

- Mix 1 x 10^6 cells (in 100 µL) with 2-5 µg of purified CAR mRNA.

- Transfer the cell-RNA mixture into a recommended electroporation tip.

- Electroporate using the pre-optimized program for human NK cells (e.g., Neon System: 1600V, 10ms, 3 pulses).

- Immediately transfer the electroporated cells into pre-warmed complete media containing cytokines.

- Post-Transfection Culture and Expansion:

- Culture the transfected cells for 24-48 hours to allow for robust CAR expression before functional assays.

- For large-scale expansion, continue co-culture with irradiated feeder cells and cytokines, with media changes every 2-3 days, for up to 14-21 days.

- Quality Control:

- Transfection Efficiency: Analyze CAR expression 18-24 hours post-electroporation by flow cytometry using a protein L or specific antigen staining.

- Viability: Assess cell viability using Trypan Blue exclusion or flow cytometry with a viability dye.

Protocol 2: Generation and Polarization of CAR-Macrophages

This protocol describes the differentiation of monocytes into macrophages and their subsequent engineering with lentiviral vectors to express a CAR, generating a stable and potent cellular product [21] [22].

3.2.1 Materials and Reagents

- Source Material: CD14+ monocytes isolated from human PBMCs using positive selection (e.g., CD14 MicroBeads, Miltenyi Biotec).

- Differentiation Media: RPMI-1640 or DMEM, supplemented with 10% heat-inactivated FBS, 100 U/mL penicillin, 100 µg/mL streptomycin, 2 mM L-glutamine, and 50 ng/mL recombinant human Macrophage Colony-Stimulating Factor (M-CSF).

- Polarization Cytokines: For M1 polarization: IFN-γ (20 ng/mL) and LPS (100 ng/mL). For M2 polarization: IL-4 (20 ng/mL) and IL-13 (20 ng/mL).

- Lentiviral Vector: Third-generation lentiviral particles encoding the CAR construct, with a titer > 1 x 10^8 IU/mL.

- Transduction Enhancer: Polybrene (5-8 µg/mL).

- Cell Dissociation Enzyme: Trypsin-EDTA (0.25%) or non-enzymatic cell dissociation buffer.

3.2.2 Step-by-Step Procedure

- Monocyte-Derived Macrophage Differentiation:

- Isolate CD14+ monocytes and seed them in tissue culture-treated plates at a density of 0.5-1 x 10^6 cells/cm2 in differentiation media.

- Culture the cells for 5-7 days, replenishing M-CSF-containing media every 2-3 days.

- Observe morphology daily; differentiated macrophages will appear large and adherent with an elongated or stellate morphology.

- Lentiviral Transduction:

- On day 6 of differentiation, gently detach macrophages using a cell scraper or non-enzymatic buffer. Count the cells.

- Re-seed the macrophages at a high density (1 x 10^6 cells/mL) in a small volume of fresh media containing M-CSF and polybrene.

- Add lentiviral particles at a Multiplicity of Infection (MOI) of 10-50. Gently mix and centrifuge the plate at 800 x g for 30-60 minutes (spinoculation) to enhance transduction efficiency.

- Incubate the cells at 37°C for 6-24 hours.

- After incubation, carefully remove the virus-containing supernatant and replace it with fresh differentiation media containing M-CSF.

- Culture the transduced macrophages for an additional 3-5 days to allow for CAR expression.

- Phenotypic and Functional Validation:

- CAR Expression: Detach CAR-M and analyze CAR expression by flow cytometry.

- Phenotype: Assess polarization markers by flow cytometry (e.g., CD80/CD86 for M1, CD206/CD163 for M2).

- Functional Assay: Proceed to the phagocytosis assay detailed in Section 3.3.2.

Protocol 3: In Vitro Functional Potency Assays

3.3.1 CAR-NK Cytotoxicity Assay

- Principle: This assay quantifies the specific lysis of target cells by CAR-NK cells in real-time.

- Procedure:

- Seed target tumor cells (e.g., GL-261 glioma cells) expressing the CAR antigen in a 96-well plate.

- After the target cells adhere, add CAR-NK cells or control NK cells at various Effector:Target (E:T) ratios (e.g., 1:1, 5:1, 10:1).

- Monitor tumor cell confluence in real-time using an live-cell imaging system (e.g., Incucyte) for 24-72 hours [25].

- Analysis: Calculate percentage cytotoxicity using the formula:

[1 - (Sample Confluence / Target Cell Only Confluence)] * 100. CAR-NK cells often exhibit rapid, CAR-independent killing initially, but CAR expression can sustain function under immunosuppressive conditions [25].

3.3.2 CAR-M Phagocytosis Assay

- Principle: This assay measures the ability of CAR-M to engulf and phagocytose antigen-expressing target cells.

- Procedure:

- Label target tumor cells with a fluorescent cell tracker dye (e.g., pHrodo Red, which fluoresces brightly upon phagocytosis and acidification).

- Co-culture pHrodo-labeled target cells with CAR-M or control macrophages at a defined E:T ratio (e.g., 1:5, macrophage:target) for 2-6 hours.

- Terminate the assay, wash the cells to remove non-phagocytosed targets, and analyze by flow cytometry.

- Analysis: Quantify the percentage of pHrodo-positive macrophages and the mean fluorescence intensity (MFI), which indicates the level of phagocytic activity. CAR-M should show significantly higher phagocytosis of antigen-positive targets compared to controls [21] [22].

The Scientist's Toolkit: Essential Research Reagents

The table below summarizes key reagents and their applications for researching CAR-NK and CAR-M platforms.

Table 1: Essential Research Reagents for CAR-NK and CAR-M Development

| Reagent / Tool | Function / Application | Example Use Case |

|---|---|---|

| NK Cell Isolation Kit | Negative selection of primary human NK cells from PBMCs. | Obtaining a pure NK cell population for engineering from donor apheresis products [25]. |

| Recombinant Human IL-2 & IL-15 | Critical cytokines for NK cell activation, expansion, and survival in culture. | Supplementing media during the expansion phase of CAR-NK cell manufacturing [24]. |

| K562-mbIL21 Feeder Cells | Genetically modified irradiated feeder cells to stimulate robust NK cell proliferation. | Large-scale ex vivo expansion of primary CAR-NK cells over 2-3 weeks [21]. |

| mRNA In Vitro Transcription Kit | For production of high-quality, capped CAR-encoding mRNA for transient expression. | Generating CAR mRNA for non-viral electroporation of primary NK cells [25]. |

| CD14 MicroBeads | Immunomagnetic positive selection of monocytes from PBMCs. | Isolating the starting population for macrophage differentiation [22]. |

| Recombinant Human M-CSF | Cytokine required for differentiation of monocytes into macrophages. | Standard differentiation of CD14+ monocytes into M0 macrophages over 5-7 days [22]. |

| Lentiviral CAR Constructs | Stable genetic modification of hard-to-transfect cells like primary macrophages. | Engineering CAR-M cells for persistent CAR expression and functional studies [21]. |

| pHrodo BioParticles | pH-sensitive fluorescent probes for quantitative flow-cytometry based phagocytosis assays. | Measuring the specific phagocytic capacity of CAR-M against target cancer cells [21]. |

Comparative Performance Data

The following table synthesizes quantitative data from recent preclinical studies to illustrate the functional profile of CAR-NK and CAR-M cells compared to traditional CAR-T cells.

Table 2: Comparative Preclinical Profile of CAR Immune Effector Cells in Solid Tumors

| Parameter | CAR-T Cells | CAR-NK Cells | CAR-Macrophages |

|---|---|---|---|

| Key Cytotoxic Mechanism | Perforin/Granzyme secretion, Fas/FasL [22] | Perforin/Granzyme, Death Receptors (FasL, TRAIL) [21] | Phagocytosis, Trogocytosis [21] |

| Antigen Recognition | CAR-dependent [25] | CAR-dependent & independent (via NKG2D, NKp30, etc.) [21] [25] | CAR-dependent [25] |

| Typical In Vitro Killing Efficacy | High, strictly CAR-dependent [25] | Very high, rapid kinetics; can be CAR-independent [25] | Moderate, reduces tumor confluence over time [25] |

| Cytokine Secretion Profile | IFN-γ, TNF-α, IL-2 [22] | IFN-γ, TNF-α, GM-CSF [21] | IL-12, TNF-α, IL-6 (pro-inflammatory) [21] [24] |

| Tumor Infiltration Capacity | Often limited in solid tumors [23] | Good; can be enhanced with chemokine receptor engineering [21] | Excellent; inherent tropism for TME [24] [23] |

| Risk of Severe CRS/ICANS | High [22] [1] | Low to Moderate [24] [22] | Not fully defined; early data suggests manageable [21] |

| "Off-the-Shelf" Potential | Limited (allogeneic rejection) [24] | High (MHC-unrestricted) [21] [24] | Under investigation [24] |

CAR-NK and CAR-M therapies represent a paradigm shift in cellular immunotherapy, moving beyond the limitations of CAR-T cells for solid tumors. The protocols and data outlined herein provide a foundational toolkit for researchers to engineer and evaluate these promising platforms. Future developments will likely focus on enhancing in vivo persistence, combating TME-induced suppression through combinatorial engineering (e.g., dominant-negative TGF-β receptors), and developing sophisticated logic-gated CAR systems to improve tumor specificity [21] [23]. The ongoing clinical translation of these innovative approaches, supported by robust and standardized manufacturing and analytical protocols, holds the key to unlocking their full therapeutic potential and expanding the reach of engineered cell therapy into the solid tumor domain.

{#context}

The Paradigm Shift: From Ex Vivo to In Vivo CAR-T Cell Manufacturing

Chimeric Antigen Receptor (CAR)-T cell therapy has revolutionized the treatment of relapsed/refractory hematological malignancies. However, the widespread adoption of this powerful modality is constrained by its complex, time-consuming, and costly ex vivo manufacturing process. This involves leukapheresis, T-cell activation, genetic modification, and expansion in specialized Good Manufacturing Practice (GMP) facilities before reinfusion into the patient [26] [27] [28]. This paradigm is now shifting toward in vivo CAR-T cell engineering, a transformative approach that generates therapeutic CAR-T cells directly within the patient's body. This application note details the limitations of conventional manufacturing, explores the platforms enabling this shift, and provides structured experimental data and protocols to guide research and development in this emerging field.

The Challenge of ConventionalEx VivoManufacturing

The established ex vivo manufacturing process presents significant logistical and clinical hurdles that limit patient access. A detailed breakdown of this workflow and its associated timelines is provided in Table 1.

Table 1: Key Steps and Challenges in Ex Vivo CAR-T Cell Manufacturing

| Manufacturing Step | Process Description | Key Challenges & Impact |

|---|---|---|

| Starting Material Collection | Leukapheresis to obtain patient's peripheral blood mononuclear cells (PBMCs) or T-cells [27]. | High variability in T-cell fitness and quantity from heavily pre-treated patients; can lead to manufacturing failure [27] [29]. |

| T-Cell Activation & Genetic Modification | T-cells are activated (e.g., with anti-CD3/CD28 beads) and transduced with viral (lentiviral/retroviral) or non-viral (electroporation) vectors to deliver the CAR gene [27] [28]. | Viral vectors require extensive safety testing and are costly; process is labor-intensive and requires stringent cleanroom environments [27] [28]. |

| Ex Vivo Expansion | Transduced T-cells are expanded in bioreactors or culture bags to achieve a therapeutic dose [27]. | Process typically takes 7-14 days, leading to critical treatment delays for patients with aggressive diseases [28]. |

| Final Formulation & Infusion | Cells are washed, concentrated, and cryopreserved for shipment and infusion [27] [30]. | Cryopreservation can cause quantitative and qualitative cell loss; the "vein-to-vein" time is several weeks [27] [30]. |

The complexity of this process contributes to an estimated cost exceeding $100,000 per patient in the West, creating a profound accessibility barrier [31] [28]. Furthermore, the resulting CAR-T cell products can exhibit heterogeneous composition and may contain exhausted T-cell subsets, which can compromise therapeutic efficacy and contribute to severe toxicities like Cytokine Release Syndrome (CRS) and Immune Effector Cell-Associated Neurotoxicity Syndrome (ICANS) [26] [29].

Emerging Platforms forIn VivoCAR-T Cell Engineering

In vivo CAR-T cell manufacturing aims to circumvent the limitations of ex vivo production by using injectable vector systems to genetically reprogram a patient's own T-cells directly in situ. The two primary technological approaches under development are viral vectors and non-viral transient expression systems, each with distinct characteristics summarized in Table 2.

Table 2: Comparison of In Vivo CAR-T Cell Manufacturing Platforms

| Platform Feature | Viral Vectors (Lentivirus, Gamma-retrovirus) | Non-Viral/Transient Vectors (LNP-mRNA) |

|---|---|---|

| CAR Expression | Long-term, persistent (genomic integration) [32]. | Short-term, transient (days to weeks) [32]. |

| Key Advantages | Single infusion can lead to durable CAR-T cell populations with memory potential; self-calibrates to disease burden [32]. | Tunable exposure via repeat dosing; potentially lower risk of genotoxicity and chronic on-target toxicities (e.g., B-cell aplasia) [32]. |

| Major Challenges | Risk of genotoxicity due to random integration; potential for uncontrolled expansion/persistence leading to protracted toxicity; pre-existing immunity to viral vectors [32]. | Liver tropism of LNPs can cause hepatotoxicity; innate immune activation by RNA/LNP; may lack potency against high tumor burden [32]. |

| Ideal Application | Oncology indications requiring deep, durable responses [32]. | Earlier-line oncology, minimal residual disease (MRD), autoimmune diseases, outpatient settings [32]. |

The field is in early clinical development, with over 35 companies actively pursuing in vivo CAR-T platforms. Early data demonstrate proof-of-concept and an acceptable safety profile in initial human trials [32]. This approach also holds promise for reprogramming other immune cells, such as Natural Killer (NK) cells and macrophages, directly in vivo [26].

Experimental Protocols forIn VivoCAR-T Cell Research

Protocol: EvaluatingIn VivoT-Cell Engraftment and CAR Expression using Viral Vectors

This protocol outlines the steps to assess the efficiency and safety of viral vector-based in vivo CAR-T generation in a pre-clinical mouse model.

- Objective: To quantify the generation, persistence, and tumor-killing capacity of CAR-T cells following a single intravenous infusion of a targeted lentiviral vector.

- Materials:

- Research Reagent Solutions:

- Targeted Lentiviral Vector: Engineered with a CAR construct (e.g., anti-CD19 scFv-41BB-CD3ζ) and T-cell-specific envelope/surface protein (e.g., CD8 scFv) to enhance T-cell tropism [26].

- NSG Mice: Immunodeficient mouse model engrafted with human CD34+ hematopoietic stem cells to create a humanized immune system [8].

- Flow Cytometry Panel: Antibodies against human CD3, CD4, CD8, and a protein tag or idiotype for detecting the specific CAR.

- qPCR/ddPCR Assay: Primers for detecting vector copy number (VCN) in peripheral blood and tissues [30].

- Research Reagent Solutions:

- Methodology:

- Animal Preparation: Use humanized NSG mice bearing established human CD19+ tumor xenografts.

- Vector Administration: Administer a single intravenous dose of the targeted lentiviral vector via tail vein injection. Include control groups receiving a non-targeted vector or saline.

- Longitudinal Monitoring:

- Tumor Monitoring: Measure tumor volume regularly via calipers or bioluminescent imaging to assess antitumor efficacy.

- Terminal Analysis: At study endpoint, harvest spleen, bone marrow, and tumor for deep phenotyping of CAR-T cells and assessment of VCN in tissues. Analyze for potential organ toxicity and vector biodistribution.

- Data Analysis:

- Correlate the peak and area-under-the-curve of CAR-T cells in blood with antitumor efficacy.

- Assess the relationship between VCN in the bone marrow and long-term CAR-T cell persistence.

- Monitor for signs of CRS/ICANS through serum cytokine levels (e.g., IL-6, IFN-γ) and clinical observation.

Protocol: Assessing Tunable CAR-T Cell Activity using LNP-mRNA

This protocol describes how to investigate the pharmacologically tunable activity of mRNA-based in vivo CAR-T cells.

- Objective: To demonstrate that repeated dosing of LNP-formulated CAR-encoding mRNA can control tumor growth in a calibrated manner.

- Materials:

- Research Reagent Solutions:

- LNP-mRNA Formulation: LNPs containing mRNA encoding an anti-BCMA or anti-CD19 CAR, optimized for in vivo T-cell delivery and reduced liver tropism [32].

- Syngeneic or Humanized Mouse Model: Bearing relevant antigen-positive tumors.

- ELISA/Luminex: For quantifying serum cytokine levels (e.g., IL-6, IFN-γ, IL-2).

- Research Reagent Solutions:

- Methodology:

- Tumor Implantation: Establish tumors in mice.

- Dosing Regimen: Initiate LNP-mRNA intravenous dosing once tumors are palpable. Test different regimens (e.g., single dose, multiple doses every 3-5 days).

- Pharmacodynamic Monitoring:

- CAR Expression: Analyze peripheral blood 24-48 hours after each dose for transient CAR expression on T-cells via flow cytometry.

- Tumor Measurement: Track tumor volume and survival.

- Toxicity Assessment: Measure cytokine levels 6-24 hours post-infusion to monitor for CRS.

- Immune Fitness Assessment: In a cohort of treated mice, analyze the differentiation and exhaustion status of CAR-T and endogenous T-cells (e.g., via Tim-3, LAG-3, PD-1 staining) to determine if transient expression mitigates exhaustion [32].

- Data Analysis:

- Compare tumor growth inhibition and overall survival across different dosing regimens.

- Correlate peak CAR expression levels after each dose with the magnitude of cytokine release and antitumor activity.

Visualization of Workflows and Signaling

The following diagrams illustrate the core logical relationship between ex vivo and in vivo manufacturing, as well as the critical signaling structure of a CAR molecule.

Diagram: CAR-T Manufacturing Paradigms. The diagram contrasts the multi-step, centralized ex vivo pathway (blue) with the streamlined in vivo pathway (red), highlighting key associated challenges and benefits.

Diagram: Second-Generation CAR Signaling Structure. The diagram details the modular domains of a CAR, from extracellular antigen recognition (yellow) to transmembrane anchoring (green) and intracellular signaling, which combines a costimulatory signal (red) with the primary CD3ζ activation domain (blue).

The Scientist's Toolkit: Key Reagents forIn VivoResearch

Table 3: Essential Research Reagents for In Vivo CAR-T Cell Development

| Reagent / Technology | Function in Research | Key Considerations |

|---|---|---|

| Targeted Viral Vectors | Engineered lentiviral/retroviral vectors for durable CAR gene delivery to T-cells in vivo [26] [32]. | Must be pseudotyped with T-cell-specific envelopes (e.g., CD8-scFv); requires rigorous biodistribution and genotoxicity studies [32]. |

| Lipid Nanoparticles (LNPs) | Non-viral delivery vehicles for in vivo delivery of CAR-encoding mRNA [32]. | Composition must be optimized for T-cell tropism over innate liver sequestration; mRNA sequence should include modified nucleotides to reduce immunogenicity [32]. |

| CAR-Encoding mRNA | The genetic payload for transient CAR expression; does not integrate into the genome [32]. | Sequence optimization (codon usage, UTRs) is critical for high translation efficiency and protein expression levels. |

| Flow Cytometry Panels | To detect and characterize in vivo generated CAR-T cells (phenotype, persistence, exhaustion) [29]. | Require specific antibodies against the CAR idiotype or a co-expressed tag, plus standard T-cell markers (CD3, CD4, CD8, CD45RO, CD62L) and exhaustion markers (PD-1, TIM-3, LAG-3). |

| qPCR/ddPCR Assays | To quantify vector copy number (VCN) for viral vectors, assessing transduction efficiency and biodistribution [30]. | Assays must be rigorously validated for sensitivity and specificity according to regulatory guidelines (e.g., Ph. Eur., USP) [30]. |

The trajectory of in vivo CAR-T cell therapy points toward rapid diversification. The short-term focus is on validating platforms against validated B-cell lineage targets (CD19, BCMA) in oncology and autoimmunity [32]. The subsequent wave will expand to solid tumor targets and non-oncological indications like regenerative medicine. Long-term, the field will evolve toward more sophisticated in vivo engineering, incorporating precision gene editing, logic-gated circuits, and spatiotemporal control of CAR expression [32]. Parallel advances in allogeneic, "off-the-shelf" CAR-T products from healthy donors will also continue, leveraging gene-editing tools like CRISPR/Cas9 to knock out the T-cell receptor (TCR) and HLA molecules to prevent graft-versus-host disease (GvHD) and host rejection [8].

In conclusion, the shift from ex vivo to in vivo CAR-T cell manufacturing represents a fundamental evolution in cell therapy. By eliminating complex logistics and high costs, this paradigm promises to democratize access to powerful CAR-T treatments, potentially extending their application beyond late-stage cancer to earlier lines of therapy and a broad spectrum of diseases. While challenges in targeting efficiency, safety, and potency remain, the convergence of viral engineering, nanomedicine, and immunobiology is paving the way for a more accessible and versatile future for cellular immunotherapy.

Advanced Manufacturing Workflows: Viral and Non-Viral Engineering Platforms

The selection of starting material is a critical foundational step in the manufacturing of Chimeric Antigen Receptor T (CAR-T) cell therapies. The conventional reliance on fresh peripheral blood mononuclear cells (PBMCs) presents significant logistical challenges and manufacturing constraints, including limited transportation windows and variable T-cell fitness in heavily pre-treated patients. Cryopreserved PBMCs offer a promising alternative, potentially enabling more flexible manufacturing timelines and the use of cells collected from patients at healthier stages or from healthy donors. This Application Note provides a comparative analysis of fresh versus cryopreserved PBMCs for CAR-T production, supported by quantitative data and detailed protocols to guide researchers and therapy developers in making evidence-based decisions for their manufacturing processes.

Comparative Performance Analysis

Cell Viability and Phenotypic Stability

Extensive research has demonstrated that cryopreserved PBMCs maintain sufficient viability and key T-cell subpopulations necessary for effective CAR-T manufacturing, even after long-term storage.

Table 1: Impact of Cryopreservation Duration on PBMC Viability and T-cell Composition

| Parameter | Fresh PBMCs | Cryopreserved (3-6 months) | Cryopreserved (12 months) | Cryopreserved (2 years) | Cryopreserved (3.5 years) |

|---|---|---|---|---|---|

| Viability (%) | Baseline [33] | 4.00-5.67% decrease [33] | Comparable to shorter cryopreservation [33] | Comparable to shorter cryopreservation [33] | 90.95% [33] |

| T-cell Proportion Stability | Baseline | Relatively stable [33] | Relatively stable [33] | Relatively stable [33] | N/A |

| Naïve T-cells (Tn) | Baseline | No significant change [33] | No significant change [33] | No significant change [33] | N/A |

| Central Memory T-cells (Tcm) | Baseline | No significant change [33] | No significant change [33] | No significant change [33] | N/A |

Studies indicate that while there is a statistically significant decrease in viability after cryopreservation, the actual reduction is only 4.00% to 5.67%, with viability remaining above 90% even after 3.5 years of storage [33]. Furthermore, the proportion of T-cells remains relatively stable post-cryopreservation, with preserved populations of naïve T-cells (Tn) and central memory T-cells (Tcm) that are crucial for long-lasting CAR-T efficacy [33].

CAR-T Functional Outcomes

Clinical and preclinical studies have demonstrated that CAR-T cells generated from cryopreserved PBMCs exhibit comparable functionality to those derived from fresh starting materials.

Table 2: CAR-T Functional Characteristics from Fresh vs. Cryopreserved PBMCs